In the dynamic landscape of printing technology, **UV DTF printers** are revolutionizing the way we approach custom apparel and promotional items. By harnessing advanced UV printing technology integrated with Direct-to-Film (DTF) capabilities, these printers deliver unparalleled quality and versatility. As businesses strive to stay competitive, finding the best UV DTF printers has become essential for anyone looking to enhance their production capabilities. With the ability to print vibrant designs onto a variety of substrates, UV DTF printers cater to the diverse needs of today’s market, from small startups to established enterprises. Moreover, they offer sustainable printing options that align with eco-conscious values, making them not just an innovative choice, but a responsible one as well.

In recent years, Direct-to-Film UV printers have become a game-changer in the world of customized printing. This innovative technology combines the efficiency of UV inks with the flexibility of DTF processes, resulting in high-quality prints that stand the test of time. As demand for individualized textile and promotional products grows, finding the ideal equipment becomes crucial for businesses aiming for a competitive edge. Whether it’s for creating unique apparel or custom designs, these printers offer an impressive range of capabilities. With increasing interest in eco-friendly solutions, many models now feature sustainable printing options, making them a smart choice for environmentally conscious entrepreneurs looking to make their mark.

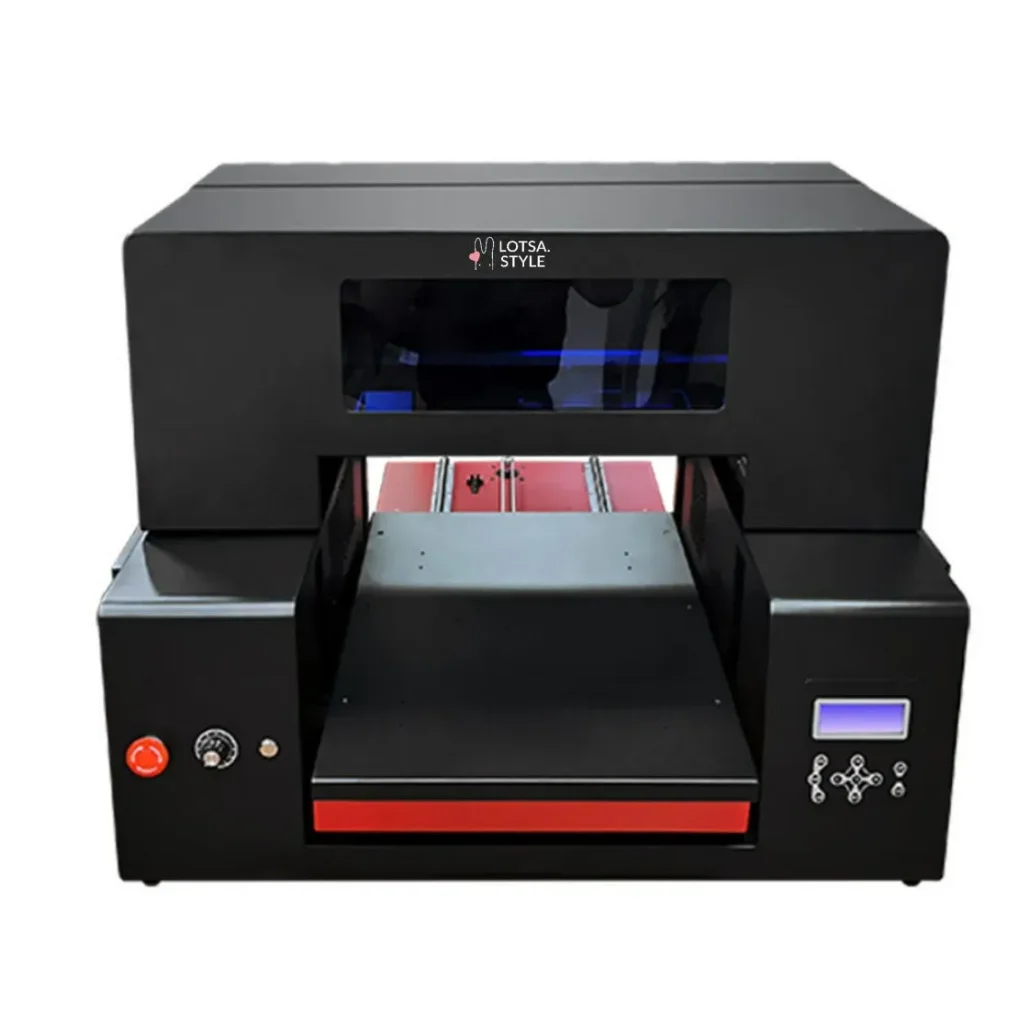

Understanding UV DTF Technology

UV DTF technology represents an innovative fusion of UV printing and Direct-to-Film (DTF) processes, allowing for the application of vibrant, long-lasting prints directly onto fabric and other materials. This combination utilizes UV-cured inks, which harden upon exposure to ultraviolet light, ensuring quick drying times and strong adhesion to a diverse array of substrates. As businesses explore these advanced options, UV DTF printers are noted for their ability to create detailed, sharp images that stand out in the competitive landscape of custom apparel printing.

Additionally, UV DTF printers are designed to handle various materials, ranging from cotton and polyester to more unconventional substrates like leather and wood. This versatility is crucial for entrepreneurs looking to diversify their product offerings. With customization becoming a top priority in modern consumer preferences, the significant capabilities of UV DTF printers place them at the forefront of the printing industry, catering to businesses eager to capitalize on on-demand production and unique designs.

Benefits of Using UV DTF Printers

One of the primary advantages of UV DTF printers is their efficiency in producing high-quality prints without the lengthy preparation typical of traditional methods. Thanks to quick curing times, businesses can significantly reduce turnaround times, allowing for faster service to customers. This is particularly beneficial in the fast-paced world of custom apparel, where timeliness can be a critical factor in achieving customer satisfaction and repeat business.

Moreover, UV DTF printing boasts impressive durability, as the cured inks are resistant to fading and wear. This durability ensures that products remain vibrant and appealing even after multiple washes or prolonged exposure to various environmental conditions. The sustainable printing aspects of UV DTF technology also resonate with eco-conscious consumers, as many models utilize ink formulations that are less harmful to the environment.

Top Features of Best UV DTF Printers

When selecting a UV DTF printer, several key features should be prioritized to ensure optimal performance. Look for models that offer expansive color gamuts to achieve vibrant, true-to-life colors that will impress customers. Resolution capabilities also play a crucial role, as higher DPI (dots per inch) translates to sharper images and finer details, especially important for intricate designs in custom apparel printing.

Another essential feature is the versatility in media handling, with an ability to accommodate different types of materials, including textiles, films, and rigid substrates. This flexibility expands creative possibilities and allows businesses to tap into various markets. Additionally, user-friendly interfaces and robust software compatibility are vital for streamlining workflow and ensuring that even novice users can operate the printers effectively.

Custom Apparel Printing with UV DTF Technologies

Custom apparel printing has witnessed a surge in popularity, and UV DTF printers have positioned themselves as vital tools for businesses in this sector. Their ability to produce intricate, high-resolution designs directly onto fabric allows for a diverse array of customization options, from personalized clothing to promotional items that stand out on shelves. This technology caters to market trends, enabling businesses to respond agilely to the needs of individual customers.

Furthermore, the ease of use associated with UV DTF printers means that businesses can engage in small-batch, on-demand printing without incurring large upfront costs typical of traditional screen printing methods. This democratization of printing technology supports micro-enterprises and hobbyists aspiring to turn their creative endeavors into profitable ventures in the growing custom apparel market.

Sustainable Printing Options in UV DTF

As sustainability becomes a growing concern among consumers and businesses alike, many UV DTF printers are designed with eco-friendly practices in mind. The utilization of UV-cured inks significantly reduces the release of volatile organic compounds (VOCs) into the environment, making these printers a safer alternative compared to traditional printing technologies. This streamlined environmental profile positions UV DTF as a viable choice for companies committed to sustainable practices.

In addition to lower emissions, UV DTF printing technology often enables the use of recycled or less wasteful materials in the production process. This focus on sustainability attracts environmentally conscious customers, who are increasingly looking for brands that align with their values. By embracing sustainable printing options, businesses can not only enhance their market appeal but also contribute positively to the global push for greener practices.

Market Trends and Future of UV DTF Printing

The demand for innovative printing solutions continues to drive advancements in the UV DTF sector. Analysts predict that the market will see substantial growth fueled by increasing customization needs across industries, including fashion, merchandise, and promotional goods. As brands seek to differentiate themselves in crowded marketplaces, UV DTF printers emerge as powerful tools for creating custom designs that resonate with consumers.

In addition, technology improvements, such as enhanced ink formulations and more efficient curing mechanisms, are expected to elevate the capabilities of UV DTF printers further. As these printers become more accessible to small businesses and startups, the landscape of custom printing is likely to evolve dramatically, making it easy for new players to enter the market and deliver high-quality, tailored products.

Frequently Asked Questions

What are the benefits of using UV DTF printers for custom apparel printing?

UV DTF printers provide several benefits for custom apparel printing, including vibrant color outputs, durability, and the ability to print on a wide variety of substrates. This technology uses UV-curable inks, which ensure excellent adhesion and longevity of prints, making them ideal for garments.

What should I consider when choosing the best UV DTF printer for my business?

When selecting the best UV DTF printer, consider factors like print quality, substrate compatibility, production speed, and budget. Additionally, look at user-friendly interfaces and whether the printer can handle various applications, from custom apparel to promotional items.

How do UV printing technology and DTF printing differ?

UV printing technology involves curing inks with ultraviolet light, allowing for faster printing on diverse materials. DTF printing, or Direct-to-Film printing, transfers designs from film to substrate using heat. UV DTF printers combine the benefits of both methods, offering exceptional versatility for custom designs.

Can UV DTF printers handle sustainable printing options?

Yes, many UV DTF printers are designed to accommodate sustainable printing options. With advancements in eco-friendly inks and efficient printing processes, businesses can utilize these printers to produce high-quality prints without compromising on environmental standards.

What types of materials can be used with UV DTF printers?

UV DTF printers are highly versatile and can print on a variety of materials, including textiles, plastics, metal, and wood. This capability makes them perfect for custom apparel printing and creating promotional products tailored to different client needs.

Are there affordable options available for entry-level users interested in UV DTF printing?

Absolutely! There are several affordable UV DTF printers designed for entry-level users. Models like A3 DTF printers are particularly popular for beginners due to their user-friendly setup and reasonable price, without compromising on print quality.

| Printer Model | Key Features | Use Case | Source |

|---|---|---|---|

| Epson SureColor F-Series Models: F170, F570 |

Excellent color accuracy; wide format capabilities; user-friendly interface. | Ideal for small to medium businesses focusing on custom apparel and textiles. | [Epson Official Blog](https://www.epson.com/For-Work/Printers) |

Summary

UV DTF printers have revolutionized the printing landscape, offering superior color reproduction and durability across various materials. As businesses increasingly seek products that stand out, UV DTF printers provide an efficient solution for achieving high-quality customized prints, particularly in textiles and promotional products. These printers not only cater to a wide array of substrates but also promote sustainability with eco-friendly ink options. As the demand for personalized printing continues to rise, adopting UV DTF technology allows enterprises, from startups to established brands, to enhance their production capabilities while maintaining exceptional print quality.