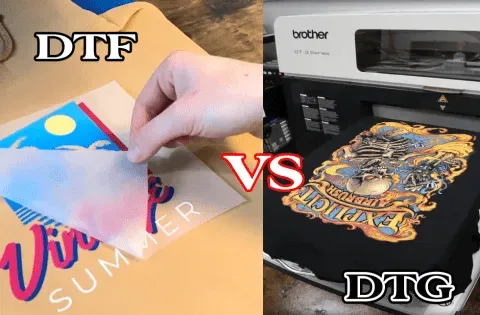

When it comes to custom apparel, selecting the right printing methodology is crucial, which is where DTF vs. DTG comes into play. Direct-to-Film (DTF) and Direct-to-Garment (DTG) are two of the most prominent printing methods available, each possessing unique features and advantages tailored to varying production needs. DTF printing excels in sustainability, versatility, and vibrant color output, making it an excellent option for larger runs or diverse fabric choices. In contrast, DTG printing offers exceptional detail and high quality, catering primarily to smaller orders or intricate designs on cotton. As the demand for innovative and environmentally friendly printing solutions grows, understanding the nuances between DTF and DTG can empower businesses to make informed choices in their custom apparel printing endeavors.

In the realm of textile printing, the distinction between Direct-to-Film and Direct-to-Garment methods is vital for manufacturers and designers alike. Also known as DTF and DTG, these innovative processes are shaping the future of fabric printing, each promising different benefits tailored to specific applications. DTF, prominent for its eco-friendly approach and compatibility with various materials, stands in stark contrast to DTG, which leverages advanced inkjet technology to deliver intricate, detailed designs. As we compare these diverse printing techniques, we delve deeper into their functionalities, production scales, and overall impacts on sustainable printing practices. This discussion is aimed at providing insights into which method best aligns with your creative vision and business objectives.

An In-Depth Look at DTF Printing Benefits

Direct-to-Film (DTF) printing stands out in the world of custom apparel due to its eco-friendly benefits. This method produces less waste compared to traditional printing techniques, which often involve excess materials and chemicals. As consumers become more aware of environmental issues, opting for DTF printing can help businesses appeal to this growing demographic that values sustainability. Furthermore, DTF’s adherence to eco-friendly practices aligns with a larger trend towards responsible manufacturing, supporting companies that wish to enhance their green credentials.

Another key benefit of DTF printing is its remarkable versatility when it comes to materials. This technology is compatible with a vast array of fabrics, including cotton, polyester, and blends, thus offering more creative freedom for designers. Unlike other printing methods, DTF allows for vibrant colors and detailed graphics to be applied to various surfaces, making it a perfect choice for those looking to experiment with unique custom apparel. With this capability, businesses can broaden their product lines and cater to diverse customer preferences.

Exploring the Advantages of DTG Printing

Direct-to-Garment (DTG) printing has become increasingly popular due to its ability to produce high-quality, detailed images directly on garments. One of the foremost advantages of DTG is its capacity to handle complex designs with intricate details, resulting in stunning and colorful prints that attract customers. This technology utilizes inkjet technology, which means that designs can be reinterpreted into vivid colors and sharp details without compromising quality. As a result, DTG printing is often the go-to choice for artists and designers who require precision and finesse in their prints.

Moreover, DTG printing is particularly advantageous for small batches and personalized items. Due to its digital nature, DTG allows for flexibility in design changes and quick turnarounds, making it feasible for bespoke orders. This flexibility means businesses can efficiently cater to individual customers or small orders without incurring substantial setup costs typically associated with other printing methods. For those focusing on niche markets or custom apparel, DTG offers a tailored approach that can result in highly satisfied clientele.

DTF vs. DTG: The Key Differences

When comparing DTF and DTG printing, understanding production volume capabilities is crucial. DTF is particularly designed for high-efficiency output, making it the ideal option for businesses looking to produce large quantities without sacrificing quality or speed. This scalability allows those in the custom apparel market to ramp up production while keeping costs low, especially beneficial for bulk orders.

On the other hand, DTG shines when it comes to producing high-quality prints for smaller quantities. While it offers exceptional detail in designs, its slower print speeds and higher ink consumption per piece can make it impractical for mass productions, where efficiency is paramount. Thus, businesses must weigh their production needs against the capabilities of each printing method to make the most appropriate choice.

Cost Analysis: DTF vs. DTG

Cost efficiency is a critical factor when deciding between DTF and DTG printing methods. For larger scale productions, DTF printing can significantly reduce costs due to its streamlined process and ability to print on various fabrics more rapidly. This efficiency can ultimately lead to greater profit margins for businesses that handle substantial orders, helping them remain competitive in the market.

Conversely, DTG tends to be more cost-prohibitive when it comes to large orders. The extended print times, along with higher ink usage, can inflate costs considerably, making, it less attractive for bulk productions. However, for businesses focusing on smaller runs or unique designs, the versatility and detail offered by DTG can justify the increased costs, allowing for a different business model targeted towards bespoke creations.

Sustainability in Apparel Printing: Why It Matters

Sustainability is becoming a central theme in the apparel industry, pushing businesses to reconsider the methods they employ for producing garments. DTF printing is often hailed for its sustainable practices, as it generates less waste and utilizes environmentally conscious materials. This process appeals not only to eco-friendly brands but also to consumers who are increasingly demanding transparency regarding the environmental impact of their purchases. With DTF, businesses can showcase their commitment to sustainability, making them more appealing to today’s conscientious shopper.

In contrast, while DTG printing also has its environmentally friendly aspects, it may not always match the efficiency of DTF in waste reduction. As the industry moves towards adopting greener practices, companies utilizing DTG must ensure proper waste management and explore ways to minimize their environmental footprint. Highlighting sustainable initiatives, whether through DTF or DTG, can have a significant positive impact on brand reputation and customer loyalty.

Choosing the Right Printing Method for Your Needs

Deciding between DTF and DTG printing based on specific business needs is essential for ensuring operational success. If your priority is to manage high-volume production, DTF is the clear winner due to its efficiency and versatility across various fabrics. Companies focused on maximizing output while minimizing costs will find that DTF more readily aligns with their objectives.

On the flip side, if your focus is more on high-quality prints for custom designs and small orders, DTG would be the appropriate choice. This method not only provides exceptional detail but also allows for personalization that can enhance customer satisfaction. Ultimately, the decision should involve a careful consideration of your target market, production scale, and the types of products you aim to create in the competitive landscape of custom apparel.

Frequently Asked Questions

What are the main differences in sustainability between DTF and DTG printing?

When comparing DTF vs. DTG printing, DTF printing is often viewed as the more sustainable option. DTF technology generally produces less waste and can use eco-friendly inks, appealing to environmentally conscious brands. On the other hand, DTG printing, while still efficient, can result in higher ink consumption during the printing process, especially with larger runs.

How does fabric compatibility vary between DTF and DTG printing methods?

DTF printing is praised for its versatility, as it can be used on a wide range of fabrics including cotton, polyester, and blends. In contrast, DTG printing excels primarily on 100% cotton fabrics. This limitation can affect the overall appeal of DTG when attempting to print on diverse materials in a custom apparel printing project.

Which printing method is more cost-effective for large orders: DTF or DTG?

For businesses looking to produce high volumes of apparel, DTF printing tends to be more cost-effective. DTF reduces costs per piece significantly due to its efficient printing process. On the other hand, DTG printing is less economical in bulk, as its slower print speeds and higher ink costs can escalate the overall expense for larger orders.

What type of designs are best suited for DTF compared to DTG printing?

When considering DTF vs. DTG for design complexity, DTF printing supports vibrant and colorful prints, making it suitable for a variety of intricate designs. However, DTG prints offer exceptional detail and precision, making it better for highly artistic designs that require complex patterns and vivid visuals. Each method has its strengths in different design scenarios.

Is DTG printing effective for personalized items compared to DTF?

Yes, DTG printing is particularly effective for small runs and personalized items. Its ability to handle quick changes allows for unique designs tailored to individual preferences. DTF printing, while also accommodating intricate designs, is optimized for larger batches, making DTG the preferred method for small-scale custom apparel printing.

Which printing method should I choose: DTF or DTG?

The choice between DTF and DTG printing hinges on your specific needs. If you require large production volumes, versatility in fabric selection, and sustainability, DTF is ideal. Conversely, if you’re focusing on high-quality, detailed prints for smaller runs, DTG might be the better option. Evaluate your goals carefully to decide which method aligns with your business strategy.

| Key Points | DTF Printing | DTG Printing |

|---|---|---|

| Definition | Transfers prints from film to fabric using heat. | Applies ink directly to fabric using inkjet technology. |

| Sustainability | Eco-friendly with less waste produced. | Less sustainable, typically more waste compared to DTF. |

| Material Compatibility | Works on various fabrics including cotton, polyester, and blends. | Best on 100% cotton fabrics; other materials may reduce quality. |

| Production Volume | Efficient for large production volumes, economical per piece. | Ideal for small runs and custom items, slower and costlier for bulk. |

| Design Complexity | Accommodates vibrant, intricate designs; adjustments for fabric may be needed. | Excels in high detail and artistic designs, ideal for complex patterns. |

| Cost Efficiency | Lower costs per unit for high volume; efficient setup. | Higher costs for larger orders due to slower print times and increased ink use. |

Summary

DTF vs. DTG printing methods are pivotal decisions in the realm of custom apparel, influencing both creativity and efficiency. When considering which method is right for you, it’s important to evaluate your business’s specific needs, whether it’s the volume of production, materials to be used, cost efficiencies, or the intricacy of designs. DTF offers sustainable, versatile, and economical solutions for high-volume prints across a variety of fabrics, while DTG provides exceptional quality for detailed designs on cotton, catering perfectly to smaller batches. Ultimately, a clear understanding of both methods allows businesses to select the best fit for their operational goals and enhances their creative potentials.