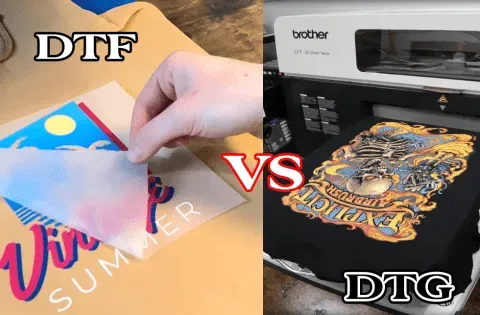

In the ever-evolving world of textile printing, the debate between DTF vs. DTG printing methods has become increasingly relevant as businesses seek the best solutions for their unique needs. Both Direct to Film (DTF) and Direct to Garment (DTG) methods offer distinct advantages, from superior print quality DTF vs DTG to their differing cost structures. Understanding these differences is essential for making informed decisions, especially when considering factors like durability, environmental impact, and production efficiency. As we explore the nuances of DTF and DTG, we will also touch upon the sustainable textile printing aspects that are becoming a priority in today’s eco-conscious market. This article aims to provide clarity and insight into the features and benefits of each printing method, guiding you to the best choice for your next project.

When it comes to the realm of textile decoration, the Direct to Film approach and the Direct to Garment technique each present unique attributes that cater to specific project requirements. Often referred to as DTF and DTG respectively, these printing technologies are fundamental in the garment industry today. The versatility of the DTF printing advantage lies in its ability to cater to a wide variety of fabrics, while the DTG printing method excels in creating intricate, high-quality designs directly on natural textiles. Additionally, businesses are now prioritizing sustainable practices, making it essential to evaluate the environmental impact of each technique. In this opening discussion, we will analyze the key distinctions between these popular methods and how they align with contemporary printing demands.

Understanding DTF Printing Technology

Direct to Film (DTF) printing has emerged as a revolutionary technique in the world of textile printing. Unlike traditional methods that rely heavily on screen printing or heat transfer techniques, DTF combines flexibility and versatility by allowing vibrant graphics to be printed on special film. This film can then be transferred onto various materials, such as cotton, polyester, and blends through a straightforward heat transfer process. With its ability to print on diverse substrates, DTF opens up opportunities for unique product offerings and customization, catering to the growing demand for personalized apparel in the textile market.

One notable advantage of DTF printing is its ability to produce high-quality results quickly and efficiently. The vibrant colors produced by DTF often rival those achieved by DTG, particularly on synthetic materials. Because DTF prints are directly adhered to the garment using heat, they often exhibit notable durability and resistance to fading even after multiple washes. This robustness makes DTF an appealing choice for businesses looking to deliver high-quality yet cost-effective prints.

Exploring DTG Printing Method

Direct to Garment (DTG) printing utilizes cutting-edge inkjet technology to print graphics directly onto fabric. This method shines in producing highly detailed and multi-colored designs, making it a preferred choice for intricate artwork and color gradients. DTG printing is particularly effective on 100% cotton fabric, seamlessly integrating the ink into the material and offering a soft, natural feel to the finished product. Because of its technological foundation, DTG can reproduce complex designs with precision, which appeals to artists and brands wanting to showcase their creativity on garments.

However, while DTG has its strengths, it also faces some challenges. The setup time for DTG printing can be longer compared to DTF, especially when dealing with large orders, making it less efficient for rapid production runs. Additionally, although recent advancements have been made to enhance the durability of DTG prints, they can still be more prone to fading and wear over time compared to DTF. As such, businesses need to consider the intended use of the garments and the frequency of washing when deciding between these two methods.

DTF vs. DTG: Print Quality Comparison

When comparing print quality between DTF and DTG, both methods have their strengths but cater to different needs. DTG printing is often exalted for its unmatched detail in high-resolution images. It excels at capturing subtle nuances and providing a wide color range, especially on natural fabrics such as cotton, which absorb inks well. This makes DTG particularly favorable for designs that require intricate details—like artwork with gradients or photographic images. The end result is generally soft to the touch, as the ink is absorbed into the fibers of the fabric.

In contrast, DTF printing has quickly gained popularity for producing vibrant colors, especially on a wider range of substrates, including synthetic materials that may not be suitable for DTG. DTF’s prints are typically durable and resistant to fading, making them ideal for designs that will see frequent wear and washing, such as sportswear or fashion items meant for teenagers. While DTG prints may offer a superior finish on certain fabrics, DTF’s versatility and strength in performance allow it to compete closely, making it an attractive option for more diverse printing needs.

Cost Comparison: DTF vs. DTG

Cost is a major factor to consider when choosing between DTF and DTG printing methods. Generally, entering the DTF market can be more financially advantageous due to lower initial equipment costs and cheaper consumables. The transfer films required for DTF are often less expensive than the specialized inks used in DTG printing. For businesses just starting out or those focusing on personalized items, DTF can provide a cost-effective solution that does not compromise on quality, responding to the demand for both affordability and versatility.

On the other hand, while DTG printing does require a higher upfront investment due to the cost of the machinery and the ongoing need for quality inks, it may prove to be more economical in the long run for businesses that anticipate large orders. DTG systems can accommodate high-volume production more effectively, especially if the design complexity demands detailed printing that customers are willing to pay more for. Ultimately, the decision comes down to understanding production needs, volume expectations, and budgeting constraints.

Durability of Prints: DTF vs. DTG

Durability is a key consideration when comparing DTF and DTG printing for apparel. DTF prints are well-regarded for their toughness and enduring nature. They are designed to withstand rigorous washing and wear conditions without compromising the quality of the print. Additionally, the heat transfer process ensures that the graphic adheres strongly to the fibers of the fabric, which prevents peeling and fading even after numerous washes. This makes DTF an attractive choice for industries that require long-lasting prints, such as sports apparel and work uniforms.

Conversely, while DTG printing delivers exceptional detail and color accuracy, the printed designs can be prone to issues like fading, cracking, or peeling when not cared for properly. The longevity of DTG prints can vary depending on the type of ink used, the fabric composition, and the washing care instructions followed by the customer. Recent technological advancements have been aimed at enhancing DTG durability, yet for businesses focused solely on durability and wear resistance, DTF might be the more practical option.

Sustainability in Textile Printing: A Closer Look

As businesses and consumers become increasingly environmentally conscious, the sustainability of printing methods has become a crucial aspect to consider. Both DTF and DTG printing are generally seen as more eco-friendly alternatives to traditional screen printing techniques due to their efficient use of materials and processes. DTF printing, in particular, is evolving to lower its carbon footprint through optimized production processes and the use of recyclable materials, contributing to a more sustainable textile industry.

DTG printing also emphasizes sustainability through the use of water-based inks that are less harmful to the environment when compared to solvent-based inks that many traditional printing methods employ. This use of water-based inks aligns with the growing demand for greener practices in the fashion industry. As customers continue to prioritize sustainability in their purchasing decisions, understanding the environmental impact of these printing methods can guide businesses in choosing the right technology for production.

Frequently Asked Questions

What is the difference in print quality between DTF vs. DTG?

When comparing print quality DTF vs. DTG, DTG printing is often regarded as the superior method since it produces high-resolution prints with intricate details, especially on 100% cotton fabrics. In contrast, DTF printing excels in vibrant colors and works well on a variety of materials, making it a versatile option that matches DTG quality in many respects.

How do the costs compare in DTF vs. DTG printing?

In a cost comparison DTF DTG, DTF printing typically has lower initial and ongoing costs due to more affordable equipment and transfer films. Conversely, DTG requires a higher upfront investment in machinery and ink supply. However, for businesses focusing on high volume orders, DTG can become more financially viable over time.

What are the advantages of DTF printing over DTG?

One of the significant DTF printing advantages is its versatility; it can print on various substrates, including synthetic materials, and offers robust durability. DTF also has faster production speeds, making it ideal for short runs and personalized items, addressing both efficiency and diverse material compatibility.

Which method is more sustainable, DTF or DTG?

Both DTF and DTG are more sustainable textile printing options compared to traditional methods. DTG uses water-based inks, which are environmentally friendly, while DTF has optimized its processes to reduce the carbon footprint, making both methods suitable for eco-conscious businesses.

How does the print durability of DTF vs. DTG compare?

In terms of durability, DTF prints are known for their excellent resistance to fading and wash damage, making them a solid choice for high-wear garments. While DTG prints offer a high-quality finish, they may fade or crack over time, although improvements in technology are enhancing their resilience.

Which printing method is best for intricate designs: DTF vs. DTG?

For intricate designs, the DTG printing method is typically favored because it allows for detailed prints and smooth color gradients, especially on natural fabrics. However, DTF can also produce high-quality prints, particularly on synthetic materials, making it a strong contender for various design complexities.

| Feature | DTF (Direct to Film) | DTG (Direct to Garment) |

|---|---|---|

| Print Quality | Vibrant colors; good durability on various materials. | Superior detail and color range; best on 100% cotton. |

| Speed & Production Efficiency | Faster production times; ideal for short runs. | Slower due to longer setup times; better for large orders. |

| Cost Considerations | Lower initial investment; more economical for startups. | Higher upfront costs; may be favorable for larger volumes. |

| Durability & Wash Resistance | Highly durable; suitable for high-wear items like sportswear. | Prone to fading or cracking over time; improvements ongoing. |

| Environmental Impact | Lower carbon footprint; growing eco-friendliness. | Utilizes water-based inks; less harmful to the environment. |

Summary

In the ongoing debate of DTF vs. DTG, both printing methods offer unique advantages catering to different requirements in the textile printing landscape. DTF stands out for its versatility and speed, making it ideal for various fabric types and short, quick runs, which is particularly appealing to small businesses and those seeking cost-effective solutions. On the other hand, DTG remains a cornerstone for high-resolution designs on natural fabrics, delivering intricate details and soft finishes that many businesses prefer for premium offerings. Ultimately, the choice between DTF and DTG will depend on individual project needs, production volumes, and budget constraints. As the industry progresses, both methods are likely to see further developments, ensuring they meet the demands of an evolving market.