In the exciting realm of fashion and personal expression, **DTF transfers** are redefining what custom apparel can be. This innovative printing method, known as Direct-to-Film (DTF) printing, allows for vibrant designs to be transferred directly onto garments with unmatched precision. Not only does DTF printing technology yield results comparable to traditional methods like screen printing, but it also offers a more cost-effective solution for businesses looking to stay competitive while reducing their environmental footprint. With an increasing emphasis on sustainable printing practices, DTF transfers meet the rising demand for eco-friendly options that appeal to conscientious consumers. By harnessing the power of DTF transfers, companies can unlock a world of endless creative possibilities in custom apparel design.

When it comes to modern printing methods for apparel, the terminology can vary, but the principles remain the same. Direct-to-Film transfers, often referred to as DTF printing, have emerged as a revolutionary approach to creating personalized garments. Known for their efficiency and versatility, these custom garment printing methods allow for detailed graphics to be applied efficiently across a wide range of fabrics. As the market trends lean more towards sustainable printing solutions, the importance of eco-conscious practices within DTF technology cannot be overstated. This advancement not only facilitates cost-effective printing but also resonates with consumers looking for environmentally friendly options in their custom apparel choices.

Understanding DTF Transfers: A Game Changer in Custom Apparel

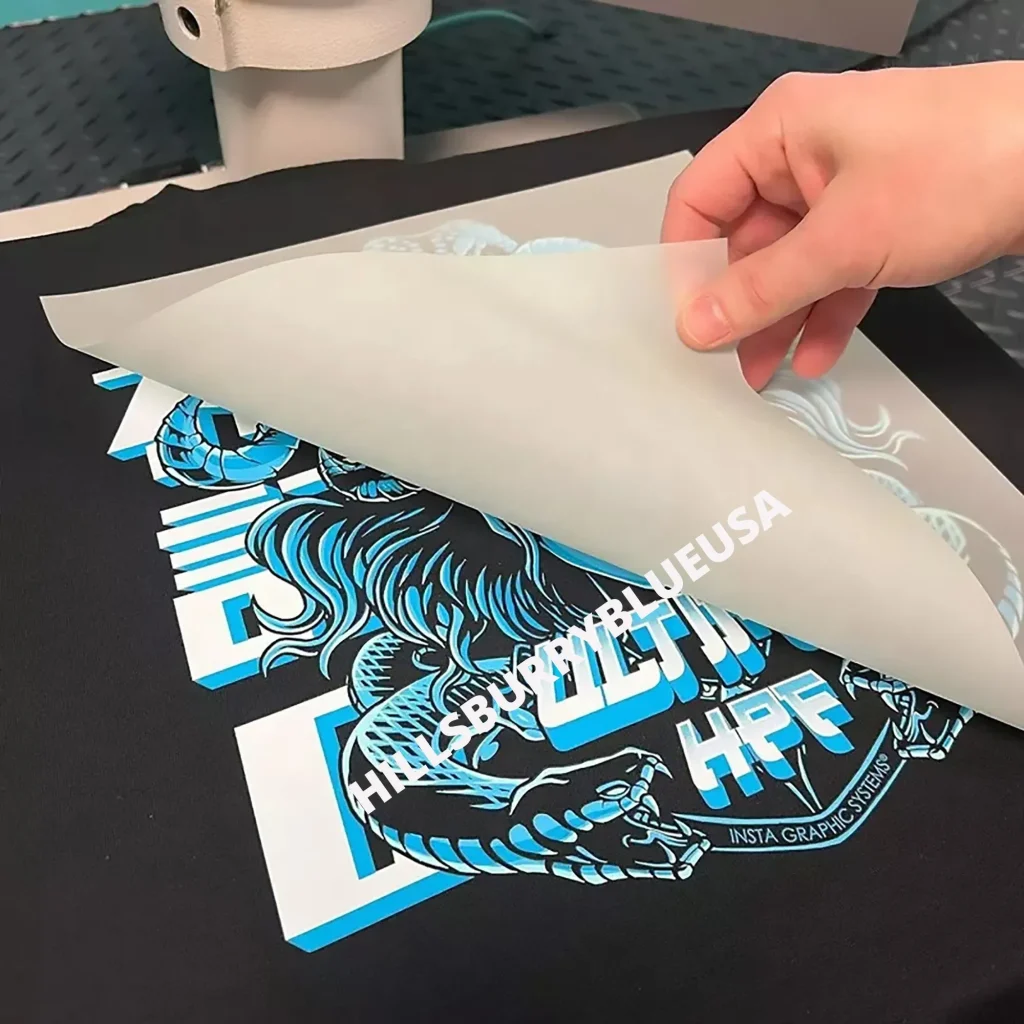

Direct-to-Film (DTF) transfers are at the forefront of modern printing technologies, designed specifically for custom apparel. This innovative technique employs a special film onto which high-quality designs are printed, allowing for vibrant graphics to be transferred onto various garments. The simplicity of the process, along with the impressive durability of the finished product, positions DTF transfers as a compelling alternative to traditional methods such as screen printing and direct-to-garment (DTG) printing. With their growing popularity, DTF transfers are reshaping the landscape of personalized fashion.

Furthermore, DTF transfers cater to a wide array of fabric types, including cotton, polyester, and poly-blends. This versatility opens new avenues for designers and businesses, enabling them to expand their product lines. As custom apparel becomes increasingly popular among consumers seeking unique expression through fashion, the ability of DTF technology to deliver high-quality prints on diverse fabrics becomes a significant competitive advantage for brands.

The Environmental Impact of DTF Transfers

Sustainability is a key concern within the printing industry, and DTF transfers are pioneering a shift towards more eco-friendly practices. Unlike traditional printing methods that often utilize harmful chemical inks, DTF printing includes options like water-based inks and sustainable transfer films. This shift not only reduces the environmental footprint of the printing process but also aligns with the values of a growing demographic of eco-conscious consumers who prioritize sustainability in their purchasing decisions.

As public awareness of environmental issues continues to rise, brands that adopt sustainable printing techniques, such as DTF transfers, stand to gain significant market advantages. Not only do these practices help minimize waste and pollution, but they also resonate deeply with consumers looking to support businesses that prioritize ecological responsibility. In embracing these sustainable practices, DTF transfers are leading the charge towards a greener future in the custom apparel industry.

Cost-Effectiveness of DTF Transfers for Small Businesses

One of the distinctive advantages of DTF transfers is their cost-effectiveness, especially for small to medium-sized businesses. Traditional printing methods often come with high setup costs and require minimum order quantities, creating financial barriers for many entrepreneurs. Conversely, DTF technology allows businesses to produce high-quality custom apparel without the significant upfront investment typically associated with screen printing. This democratization of custom printing enables startups to experiment with their designs and cater to niche markets efficiently.

Moreover, the reduced waste associated with on-demand printing makes DTF transfers a financially smart choice. As businesses can produce apparel tailored to immediate consumer demand, they avoid the pitfalls of overproduction and unsold inventory. This adaptability not only improves profit margins but also streamlines operations, allowing brands to respond quickly to emerging trends and consumer preferences.

The Rise of Direct-to-Film Technology in Fashion

The rapid growth of DTF printing has been fueled by technological advances that enhance the quality and efficiency of the process. Innovations in printing technology, such as improvements in printer capabilities and ink formulations, have resulted in unmatched vibrancy and clarity in custom designs. These advancements enable businesses to offer a wider variety of high-quality products while maintaining exceptional turnaround times.

The rising demand for personalized fashion has also contributed to the increased adoption of DTF technology. As consumers increasingly seek unique, customized apparel options, brands that utilize DTF transfers are better positioned to meet this demand. By leveraging the strengths of DTF printing, companies can stand out in a crowded market, cultivate customer loyalty, and build stronger brand identities that resonate with their target audiences.

Expanding Customization Possibilities with DTF Transfers

DTF transfers excel in their ability to produce intricate designs and vibrant color palettes, making them perfect for custom apparel that demands a high level of detail. This technology not only supports a wide variety of design styles but also enables creators to experiment with different artistic approaches, all while ensuring that quality is never compromised. As more designers embrace DTF, the possibilities for creating truly unique garments become virtually limitless.

Additionally, the adaptability of DTF printing extends beyond just fabric choices. Entrepreneurs can apply DTF technology to a diverse range of products, from everyday wear like t-shirts and sweatshirts to promotional items and accessories. This flexibility helps businesses expand their offerings and reach broader audiences, ultimately enhancing revenue streams and driving growth in the competitive landscape of custom apparel.

Future Trends in DTF Transfers and Custom Apparel

Looking ahead, the future of DTF transfers appears promising, with ongoing advancements in printing technology likely to advance the capabilities of this method even further. As new inks are developed and printer technologies evolve, we can expect improvements in both efficiency and product quality. It is essential for businesses to stay abreast of these developments to remain competitive and capture emerging market opportunities.

Moreover, with consumer preferences continuously shifting towards more personalized and eco-friendly products, DTF transfers are ideally positioned to thrive in this landscape. The combination of affordability, adaptability, and sustainable practices ensures that DTF technology will continue to shape the future of custom apparel, allowing brands to meet customer demands in innovative and responsible ways.

Frequently Asked Questions

What are DTF transfers and how do they work?

DTF transfers, or Direct-to-Film transfers, are a modern printing technology that involves printing designs onto a special film, which is then applied to various garments. This method uses advanced ink formulations, allowing for vibrant colors and excellent durability, making it an attractive option for custom apparel.

What benefits do DTF transfers offer for custom apparel businesses?

DTF transfers provide several advantages for custom apparel businesses, including cost-effectiveness, as they require lower minimum order quantities compared to traditional printing methods. Additionally, DTF printing technology supports quick turnaround times and high-quality results, enabling businesses to respond swiftly to consumer demands.

How does DTF printing technology contribute to sustainable printing practices?

DTF printing technology enhances sustainable printing by utilizing water-based inks and eco-friendly transfer films. This reduces the environmental impact associated with traditional apparel manufacturing, thus appealing to eco-conscious consumers who prioritize sustainable practices in their purchases.

What fabric types can DTF transfers be applied to?

DTF transfers are highly versatile and can adhere to a variety of fabric types, including cotton, polyester, and fabric blends. This adaptability enables businesses to offer a broad range of custom apparel options, from shirts to bags, catering to diverse consumer preferences.

Is DTF printing technology user-friendly for beginners?

Yes, DTF printing technology has become increasingly user-friendly, with many printers and software options available that allow even those without technical backgrounds to create custom transfers easily. This accessibility encourages more entrepreneurs to enter the custom apparel market.

What is the growth outlook for DTF printing in the custom apparel market?

The DTF printing market is expected to see significant growth, with projections indicating a compound annual growth rate (CAGR) of approximately 7.5% through 2030. This growth is driven by the rising demand for personalized and custom apparel, making DTF transfers a promising investment for businesses.

| Key Point | Description |

|---|---|

| What Are DTF Transfers? | A revolutionary printing method where designs are printed onto a special film and then transferred onto garments, offering quality similar to screen printing and DTG printing. |

| Technology Advances | Recent improvements have led to better color vibrancy, faster speeds, and adherence to various fabrics, enhancing the appeal for businesses. |

| Cost-Effectiveness | DTF transfers lower financial barriers for small to medium businesses, reducing setup costs and allowing for lower minimum orders, enabling responsive design testing. |

| Sustainability in Printing | With a focus on eco-friendly practices, DTF printing uses water-based inks and sustainable films, aligning with consumer preferences for environmentally responsible products. |

| Market Growth and Demand | Projected to grow at a CAGR of 7.5% through 2030 due to increasing demand for personalized apparel, DTF transfers are set for significant market expansion. |

| User-Friendly Applications | Emerging user-friendly printers and software facilitate easy creation of custom transfers, promoting innovation by empowering non-technical users. |

| Versatility Across Fabrics | DTF transfers can adhere to a wide range of fabrics, making it suitable for various products from t-shirts to accessories, thus catering to diverse markets. |

Summary

DTF Transfers are revolutionizing the custom apparel industry, bringing forth a myriad of benefits that cater to both businesses and consumers. This innovative printing technology not only enhances design quality and efficiency, but also promotes cost savings, sustainability, and user-friendliness. By enabling easy access to high-quality custom designs, DTF Transfers are transforming the way businesses cater to customer preferences in an increasingly personalized market. As more entrepreneurs adopt this technology, the future of custom apparel looks promising, with DTF transfers leading the way in creativity and innovation.