DTF transfers, or Direct to Film transfers, are revolutionizing the landscape of custom printing by merging advanced digital printing technology with sustainable practices. As the demand for personalized designs grows, DTF printing stands out as an attractive option for businesses eager to offer high-quality, vibrant prints that cater to individual tastes. This cutting-edge technique not only allows for intricate designs and sharp color reproduction but also promotes environmentally-conscious printing methods. In this guide, we’ll delve into the numerous advantages of DTF transfers, revealing why they are becoming the preferred choice for those in the custom printing industry. With DTF technology, companies can meet the evolving expectations of consumers while also enjoying the benefits of reduced waste and increased versatility in materials.

Often referred to as Direct to Film printing, DTF technology is setting a new standard in the custom printing sector by utilizing innovative digital techniques to create stunning designs. This method of film transfer printing enables creators to achieve intricate artwork on various materials, meeting the diverse demands of modern consumers. By combining qualities of traditional printing with advanced innovations, businesses can leverage DTF solutions to enhance product offerings and stand out in a crowded marketplace. The versatility of this technique, along with its emphasis on sustainable practices, makes it an appealing choice for those committed to reducing their environmental footprint while still delivering exceptional quality. As we explore this topic further, we will highlight why DTF print methods are gaining traction and reshaping the future of customized products.

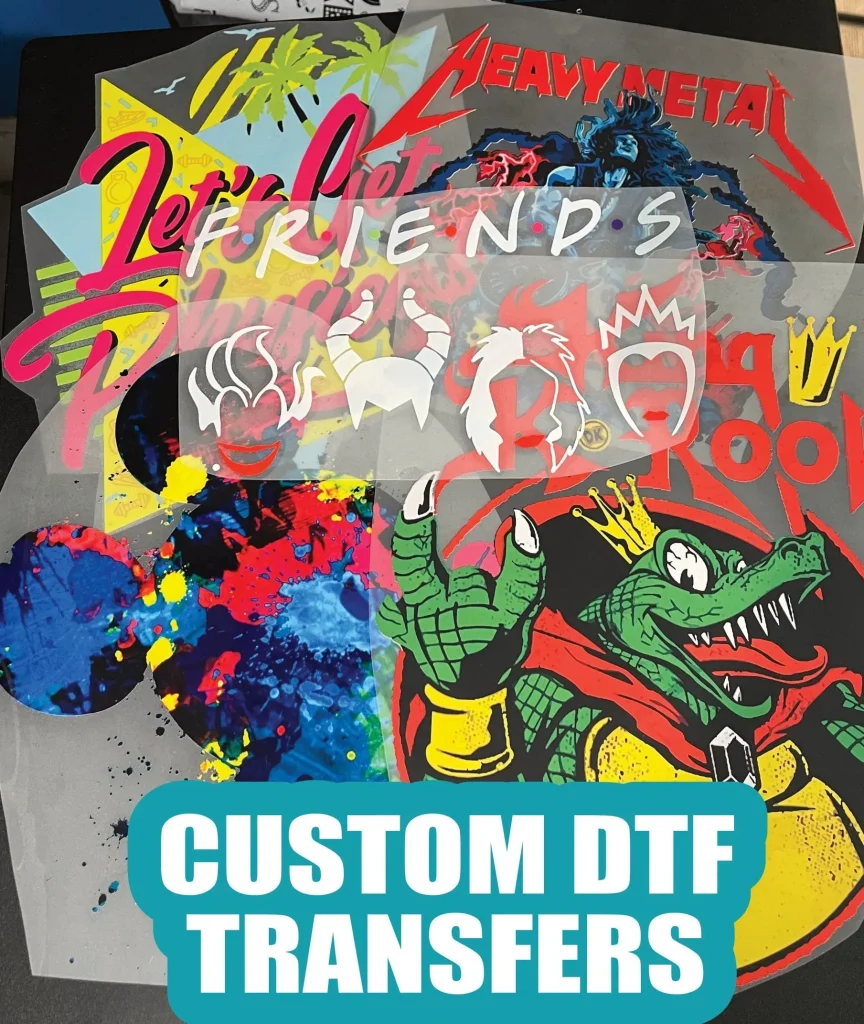

What is DTF Printing and How Does it Work?

DTF printing, or Direct to Film printing, is an innovative printing technology that allows for vibrant and detailed designs to be transferred onto various materials. The process begins by printing designs onto a specialized film using water-based inks, which are then coated with a hot melt adhesive. Once this step is complete, the printed film is heated to activate the adhesive, allowing the design to bond effectively to the target surface, such as fabrics, ceramics, or even wood. This unique printing method stands out by its ability to produce intricate patterns and vivid colors that captivate customers while also maintaining a level of sustainability, as it uses less water compared to traditional methods.

The versatility of DTF printing allows businesses to expand their offerings effortlessly. Whether it’s custom apparel, promotional items, or home décor, the adaptability of DTF technology enables designers to explore limitless creative possibilities. Furthermore, the ability to work with various substrates means that businesses are not confined to a single type of product, enhancing their market reach and customer satisfaction.

Understanding the mechanics of DTF printing is essential for businesses seeking to enter the custom printing landscape. The process not only ensures high-quality output but also minimizes costs by reducing waste in production. Unlike traditional screen printing, which requires significant setup and ink resources, DTF is a more streamlined approach that allows for shorter runs. This is particularly advantageous for small businesses or startups that wish to test designs on a smaller scale before committing to larger orders.

The Benefits of Using DTF Transfers for Custom Printing

Choosing DTF transfers for custom printing brings a host of advantages. One of the most notable benefits is the high level of detail and quality they offer. DTF technology permits the printing of intricate designs with gradients, shades, and multi-colored patterns that elevate the perceived value of custom products. This creates an enjoyable customer experience, as the end products are often more visually appealing and durable than those produced by traditional printing methods.

Additionally, DTF transfers are straightforward to apply, making them user-friendly for businesses of all sizes. The ease with which these transfers can be utilized translates to faster turnaround times and less operational downtime. With minimal training required, even novices can quickly become adept at utilizing DTF technology to produce stunning prints, thereby boosting productivity and profitability in the long run.

Moreover, the cost-effectiveness of DTF transfers makes them an attractive option in the competitive world of custom printing. By streamlining the printing process and reducing expenditures associated with setup and waste, businesses can achieve significant savings. These savings can be passed onto customers, making DTF products a widely preferred option for businesses looking to gain a competitive edge in the market. As consumer demand for unique and personalized products continues to grow, DTF printing stands out as a vital tool for success.

Sustainability in DTF Printing

As sustainability becomes a pressing concern for many industries, DTF printing technology offers an eco-friendly alternative to traditional methods. By utilizing water-based inks and producing less waste throughout the printing process, DTF transfers align with the growing demand for sustainable printing options. This not only satisfies the environmental ethics of the modern consumer but also allows businesses to market themselves as environmentally responsible—a compelling selling point in today’s eco-conscious marketplace.

In addition to its lower environmental impact, DTF printing technology can also leverage more sustainable operational practices. Companies can adopt practices such as recycling film and deploying digital printing methods that reduce chemical use and energy consumption. By integrating sustainable practices, businesses can enhance their reputation while contributing positively to the environment, making DTF a forward-thinking option in the custom printing sector.

The shift towards sustainable printing has encouraged many businesses to re-evaluate their operations, and DTF technology provides an excellent pathway for this transition. By investing in DTF printing, companies not only commit to improving sustainability but also respond to consumer preferences for products that are environmentally-conscious. This desire for sustainability can translate to increased customer loyalty and brand reputation, making it a wise investment for businesses looking to thrive in an evolving market.

DTF vs. Traditional Printing Methods: A Comparison

When comparing DTF printing with traditional methods like screen printing and direct-to-garment (DTG) printing, it is crucial to consider several key factors such as setup time, cost, and versatility. Traditional printing methods often involve lengthy setups and a steep upfront investment, especially when dealing with intricate designs that require multiple colors. Conversely, DTF printing significantly reduces the setup time, allowing for quick production and flexibility in switching between designs without incurring excess costs.

Moreover, DTF’s compatibility with a wide range of materials gives it a strong advantage over traditional methods. While screen printing can be limited to specific fabric types, DTF can effectively print on cotton, polyester, and blends, making it a superior choice for businesses aiming to cater to a diverse clientele. This versatility encourages broader product offerings, allowing companies to stay competitive in a market that increasingly demands variety.

Furthermore, the quality of output is another distinguishing factor. DTF printing produces high-quality visuals with a level of detail and vibrancy that is often unmatched by traditional methods. Customers are consistently drawn to the rich finishes and aesthetics achieved through DTF transfers, leading to a higher satisfaction rate. Overall, those looking to innovate and expand their services in the custom printing realm will find DTF technology more advantageous when weighed against traditional printing options.

Key Trends in DTF Printing Technology

As DTF printing continues to gain traction, several current trends are shaping its future. One notable trend is the increase in technological advancements within the industry. Manufacturers continuously innovate, developing new printers and inks designed to enhance the quality and speed of production. These innovations not only improve the printing process but also adapt to meet consumer demands for greater customization and personal expression in their purchases.

Additionally, the strategic partnerships between businesses and DTF technology providers play a significant role in fueling growth. By collaborating with manufacturers, businesses can access the latest technologies and expertise, enabling them to refine their offerings and improve service quality. These partnerships encourage the exchange of knowledge, leading to enhanced production capabilities and the overall advancement of DTF printing as a significant player in custom printing.

Moreover, a shift in marketing strategies is occurring within the DTF printing sector. As brands recognize the need to communicate their sustainability efforts, they are effectively using DTF prints as a focal point of their marketing messages. Messaging that highlights the high-quality and eco-friendly aspects of DTF will help businesses enhance their visibility and resonate with like-minded consumers, further cementing their position in a competitive market.

Frequently Asked Questions

What are DTF Transfers and how do they work in custom printing?

DTF transfers, or Direct to Film transfers, utilize specialized ink to print designs onto a film, which are then applied to various surfaces like textiles. This innovative process allows for high-resolution images and intricate designs, making it a popular choice for custom printing.

What are the key advantages of using DTF printing technology?

The key advantages of DTF printing technology include superior print quality with vibrant colors, versatility across different fabrics, cost-effectiveness for short runs, ease of use, and an environmentally friendly approach compared to traditional methods.

How does DTF printing compare to traditional custom printing methods?

DTF printing differs from traditional methods like screen printing by offering higher resolution designs and requiring less setup. It’s cost-effective, reduces waste, and allows for printing on a variety of materials, making it a flexible solution in custom printing.

Can DTF transfers be used for sustainable printing practices?

Yes, DTF transfers support sustainable printing practices by utilizing less water and producing less waste than many traditional techniques. Many DTF printing processes also incorporate eco-friendly inks, appealing to environmentally conscious consumers.

What types of products can be created using DTF transfers?

DTF transfers can be used to create a wide array of products including custom apparel, promotional merchandise, and home goods. Their versatility makes them ideal for businesses seeking to cater to diverse customer needs in custom printing.

Is DTF printing technology suitable for small businesses in the custom printing market?

Absolutely! DTF printing technology is particularly suitable for small to medium-sized businesses due to its cost-effectiveness and ease of integration into existing operations, allowing for quick adaptation and production of high-quality custom prints.

| Key Point | Description |

|---|---|

| Overview of DTF Printing | DTF printing uses specialized ink to create vibrant designs on a film which can be applied to various surfaces, offering intricate detail and minimizing waste. |

| Quality and Detail | Produces high-resolution outputs with rich colors and complex designs, ideal for custom apparel and promotional materials. |

| Versatility | Compatible with a range of fabrics including cotton and polyester, DTF technology caters to diverse customer needs. |

| Cost-Effectiveness | Minimizes setup costs and waste, making it ideal for small to medium-sized production runs. |

| Ease of Use | User-friendly with minimal training required, facilitating easy integration into existing printing operations. |

| Environmental Impact | Uses less water and produces less waste compared to traditional printing methods, appealing to eco-conscious consumers. |

| Industry Trends | Growing market demand, technological innovations, and strategic partnerships are driving the adoption of DTF printing. |

Summary

DTF transfers are transforming the landscape of custom printing by offering unmatched quality, versatility, and sustainability. This innovative printing technique caters to the modern consumer’s demand for high-quality, customized products while being cost-effective and environmentally friendly. As the technology continues to evolve, DTF transfers are set to become the preferred choice for businesses looking to elevate their print offerings, resulting in a brighter future for the custom printing industry.