DTF transfers, short for Direct to Film transfers, are revolutionizing the print business landscape with their blend of sophistication and user-friendliness. This technique enables entrepreneurs to produce high-quality prints that are perfect for custom apparel, tapping into the growing demand for unique and personalized products. In this comprehensive DTF printing guide, you will discover how to do DTF transfers effectively, understand the necessary DTF printing equipment, and even explore eco-friendly DTF printing options that cater to environmentally conscious consumers. As you embark on starting a DTF business, mastering these fundamentals will set you on the path to success in this vibrant industry. Get ready to dive deep into the world of DTF, where creativity meets efficiency!

When it comes to modern printing methods, Direct to Film printing stands out as a transformative option for those venturing into the realm of custom designs. This process involves printing artwork onto a specialized film, which is then applied to textiles or other materials using heat, creating stunning visuals that captivate customers. With this innovative technique, print entrepreneurs can explore various avenues, including the development of personalized clothing and merchandise while leveraging eco-friendly solutions that align with sustainability trends. The key to succeeding lies not only in understanding how to execute DTF transfers but also in using the right printing equipment to ensure vibrant and intricate outputs. By embracing this contemporary approach to printing, you’ll be well-equipped to launch or enhance your DTF print business.

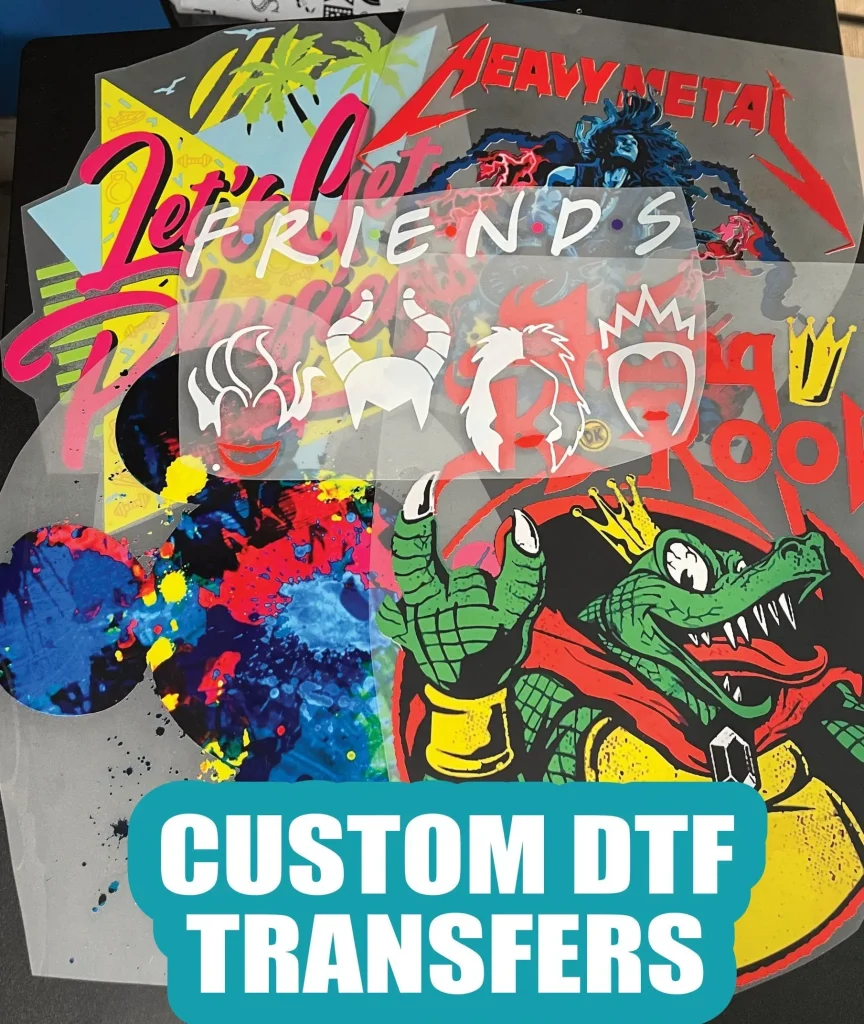

Introduction to DTF Transfers: A Game Changer in Printing

Direct to Film (DTF) transfers have rapidly established themselves as a revolutionary technique in the world of printing, especially for those venturing into custom apparel. Unlike traditional methods, DTF allows for vibrant and intricate designs to be seamlessly applied to various fabric types. This innovation not only optimizes production efficiency but also caters to a growing market that appreciates diversity in print styles.

For entrepreneurs considering a DTF business, the shift towards this method represents a significant opportunity. By understanding the nuances of DTF technology, including its operational requirements and potential market impact, newcomers can effectively position themselves within the competitive printing landscape.

Understanding DTF Printing: Process and Benefits

DTF printing defines the process of printing designs onto a specialized film, which is subsequently transferred to fabric using heat. This technique stands out due to its ability to produce vibrant colors and highly detailed graphics, appealing to businesses focused on custom apparel production. The reduced setup time compared to traditional printing makes it a preferred choice for many.

Furthermore, DTF printing offers eco-friendly advantages, as it minimizes waste inherent in the production process. With sustainability being a priority for many consumers, businesses adopting DTF can align themselves with these values, attracting a conscientious customer base.

Essential Equipment for DTF Transfers: What You Need to Start

To successfully embark on your DTF printing journey, investing in the right equipment is crucial. A reliable DTF printer, such as the LOKLiK iPrinter DTF-A3-XP600, stands out for its user-friendliness and comprehensive supply package. This includes everything from specialized inks to transfer films, ensuring a seamless start to your operations.

Additionally, a high-quality heat press machine is indispensable for transferring designs accurately. The ability to control temperature and pressure will impact the finish of your products, making this investment critical for ensuring high-quality outputs in your print business.

Mastering the DTF Process: Step-by-Step Guide

Before launching your DTF printing venture, it’s essential to comprehensively understand the entire process from design creation to final application. Start by creating impressive designs that represent your brand’s identity using graphic design software. This initial step sets the foundation for everything that follows.

Once your designs are ready, the printing process onto transfer film comes into play, requiring attention to settings such as resolution. Following this, the application of heat transfer powder and its curing process are equally important to ensure a professional finish. Mastery of these steps can significantly elevate the quality of prints produced.

Marketing Strategies for Your DTF Printing Business

After setting up your equipment and familiarizing yourself with the DTF process, effective marketing is key to attracting customers. Leveraging social media platforms like Instagram is an excellent way to showcase your designs and engage with potential clients visually.

In addition, establishing an online store can extend your reach significantly. Optimize your website with SEO strategies to improve search visibility. Collaborations with local businesses can also provide cross-promotional opportunities, enhancing your credibility and expanding your customer base.

Embracing Sustainability in DTF Printing Practices

The emphasis on eco-friendly practices in today’s printing landscape cannot be overstated. DTF printing, with its reduced waste generation and sustainable sourcing of materials, aligns perfectly with environmental initiatives. This conscientious approach can resonate with eco-aware consumers, positioning your business distinctively in the market.

By integrating sustainable practices into your DTF printing operations, not only do you contribute positively to the environment, but you also enhance your brand image. Consumers are highly inclined to support businesses that prioritize eco-friendliness, showing that your commitment to sustainability can, in turn, drive profitability.

Frequently Asked Questions

What is DTF printing and how does it work?

DTF printing, or Direct to Film printing, is a method where designs are first printed onto a special film, which is then transferred onto fabrics using heat and pressure. This process allows for vibrant colors and intricate designs, making it ideal for custom apparel.

What equipment do I need to start DTF transfers?

To start with DTF transfers, you’ll need a DTF printer, a high-quality heat press machine, DTF transfer film, heat transfer powder, and graphic design software. Investing in quality equipment is essential for successful prints.

Is DTF printing an eco-friendly option?

Yes, DTF printing is considered eco-friendly as it minimizes waste compared to traditional printing methods. It aligns with sustainability trends and can attract environmentally conscious customers.

How do I do DTF transfers?

To do DTF transfers, begin by creating your design in graphic design software. Print your design onto the transfer film, apply heat transfer powder, cure it in a heat press, and finally, press it onto the fabric to achieve a high-quality print.

What are the benefits of starting a DTF business?

Starting a DTF business offers numerous benefits including lower setup costs compared to traditional printing, faster turnaround times, and the ability to create unique, custom products that appeal to a wide market.

What is the best way to market my DTF printing business?

Effective marketing strategies for a DTF printing business include leveraging social media platforms, creating an online store, partnering with local businesses, and encouraging customer feedback to build credibility and attract more clients.

| Key Points | Details |

|---|---|

| Understanding DTF Printing | DTF (Direct to Film) transfers allow for vibrant designs and quicker setup compared to traditional methods, appealing to custom apparel businesses. |

| Advantages of DTF Printing | Reduced setup time, minimal waste, and eco-friendly processes cater to environmentally conscious consumers. |

| Recent Innovations | Companies like EazyDTF have added advanced printers to enhance quality and speed, making the market more accessible with lower investment needs. |

| Essential Equipment | A DTF printer, heat press machine, transfer film, heat transfer powder, and graphic design software are necessary tools to start. |

| Learning the DTF Process | Key steps include designing, printing, applying powder, curing, and transferring to fabric. |

| Marketing Strategies | Utilize social media, create an online store, build local partnerships, and encourage customer feedback to boost business. |

Summary

DTF Transfers are transforming the print industry by offering an efficient and high-quality solution for customizing products. By understanding the basics, investing in the right equipment, and implementing effective marketing techniques, print entrepreneurs can thrive in this exciting market. With the technology becoming more accessible and the demand for sustainable practices on the rise, now is a prime time to embrace the opportunities presented by DTF Transfers. Your venture into this innovative printing method could lead to exceptional growth and success, enabling you to create unique products that resonate with a diverse audience.