DTF transfers, or Direct-to-Film transfers, are rapidly transforming the landscape of garment printing and customization. This innovative technique allows for the application of detailed and vibrant designs directly onto various fabrics, elevating the standard of quality in custom apparel. With numerous DTF printing benefits such as exceptional durability, versatility, and cost-effective printing solutions, it’s clear why businesses are opting for this technology over traditional methods. Furthermore, the advantages of DTF extend beyond simple aesthetics, offering users a practical and user-friendly approach to creating stunning designs. As the competition intensifies in the custom printing market, understanding the benefits of DTF vs DTG and its role in sustainable practices could prove essential for any ambitious creator or business.

In the realm of modern garment personalization, the emergence of Direct-to-Film (DTF) transfers marks a significant shift in printing methodology. This process involves the transfer of intricate designs onto a specialized film that can be applied to a wide array of fabric types, making it a versatile choice for enthusiasts and professionals alike. The key to its growing popularity lies not just in its user-friendliness but also in the undeniable DTF printing benefits, including enhanced durability and lower production costs. When comparing DTF to traditional printing methods such as Direct-to-Garment (DTG), it’s essential to recognize how advantages of DTF offer a compelling alternative, providing businesses with reliable and high-quality printing solutions. Embracing DTF technology allows custom apparel makers to expand their creative horizons while adhering to current trends in sustainability.

Understanding Direct-to-Film (DTF) Transfers

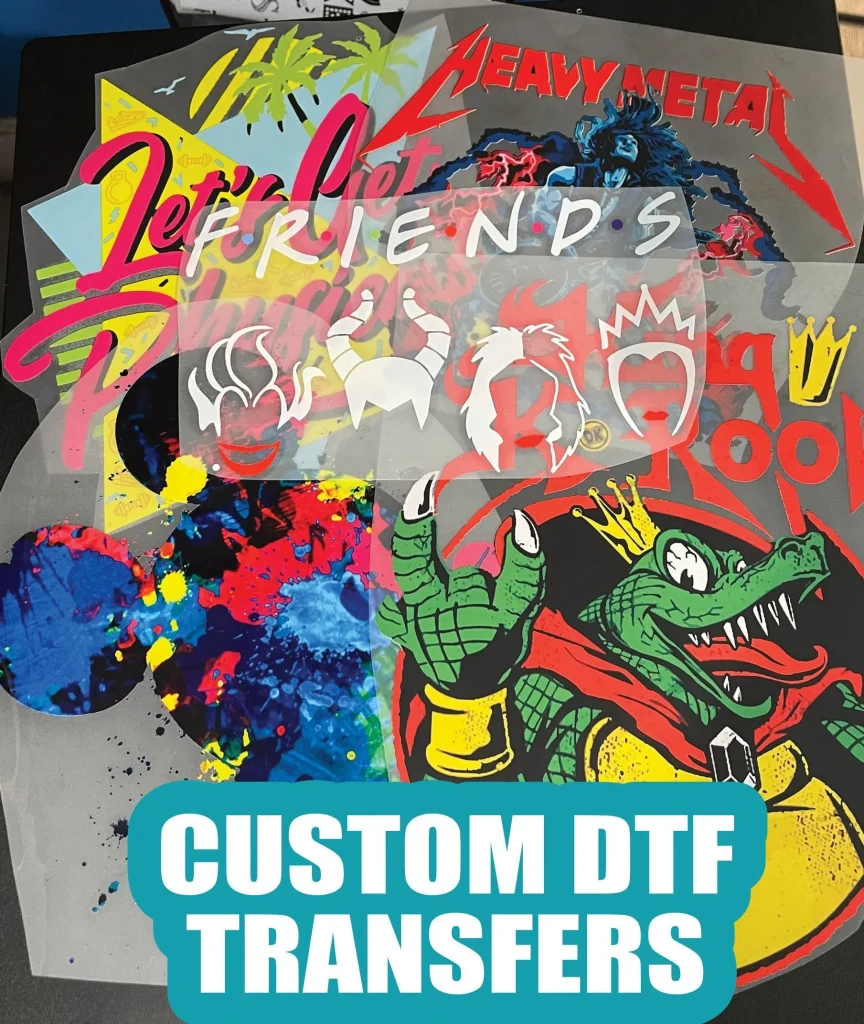

Direct-to-Film (DTF) transfers represent a cutting-edge advancement within printing technology, particularly suited for the garment industry. This process involves printing intricate designs onto a special film, which is then heat transferred to fabric, resulting in high-quality, durable graphics. DTF transfers have gained traction due to their ability to combine vibrant color output with fine detail, making them ideal for creative applications ranging from fashion apparel to promotional merchandise.

Unlike traditional printing methods, DTF printing offers extensive compatibility with various fabric types, including cotton, polyester, and blends. This versatility allows businesses to cater to diverse clientele by customizing a wide array of clothing items, elevating the potential for creativity and market reach. Understanding the mechanics and advantages of DTF transfers is essential for any business owner looking to innovate and streamline their printing processes.

The Benefits of DTF Printing for Custom Apparel

DTF printing offers numerous benefits that make it an appealing choice for custom apparel makers. Among these advantages, the vividness and clarity of images stand out. The DTF process allows for intricate designs that are often lost in traditional techniques like screen printing. These sharp visuals not only enhance the aesthetic appeal of garments but also deliver a professional look, essential for brand image and customer satisfaction.

Furthermore, the user-friendly nature of the DTF process is a significant draw. The method simplifies production, reducing the skill barrier for newcomers while empowering experienced printers to work efficiently. With just a few steps—printing on film, applying adhesive powder, and utilizing a heat press—businesses can achieve impressive results without extensive training or complex setups.

DTF Transfers: Versatility and Material Compatibility

One of the most remarkable qualities of DTF transfers is their versatility when it comes to fabric compatibility. Whether it’s lightweight cotton or heavy-duty synthetics, DTF demonstrates exceptional adaptability across a variety of materials. This feature enables businesses to expand their product offerings, allowing them to venture into different markets, including athletic wear, promotional items, and fashion goods without the worry of compromising on print quality.

This extensive compatibility not only appeals to garment makers, but it also reassures customers that they can have their designs printed on the materials of their choice. With DTF printing, the opportunities to create tailored solutions for diverse consumer needs are virtually limitless, providing a significant edge over other printing methods that may be restricted by material choices.

Comparing DTF to DTG Printing

When considering direct-to-film (DTF) transfers versus direct-to-garment (DTG) printing, several key differences emerge that impact decision-making for businesses. While DTG is known for its ability to print directly onto garments providing intricate detail, DTF offers a unique approach that lends itself to greater versatility across a range of fabrics. DTF’s film application allows for consistent quality across various material types while maintaining high resolution, leveling the playing field between various printing methods.

Additionally, when it comes to production capabilities, DTF printing tends to be more efficient for small batch orders. Businesses can customize a limited number of items without the extensive setup costs that often come with DTG printing. This cost-effectiveness is particularly advantageous for startups or individual creators aiming to cater to niche markets or customers looking for limited edition items.

The Cost-Effectiveness of DTF Printing

Transitioning to DTF printing can significantly optimize the financial aspect of garment creation. The cost-effective nature of DTF technology allows small businesses to produce high-quality prints at lower investment levels than traditional screen printing. This is especially true for single or small batch runs, eliminating the need for costly screen setup or large quantities of orders.

Moreover, DTF allows printers to scale their operations without incurring excessive costs, which is crucial for managing budgets effectively. As a result, this method empowers creators to experiment with their offerings without financial constraints, ultimately enabling them to satisfy customer demands and adapt to market fluctuations.

Low Waste Production with DTF Technology

In today’s eco-conscious marketplace, sustainability is paramount, and DTF transfers shine when it comes to reducing waste. Traditional printing methods often lead to excess materials, whether from misprints or unused inks. In contrast, DTF technology minimizes waste through precision printing techniques that require only the necessary materials for each design, leading to a cleaner production process.

By adopting DTF printing, businesses can demonstrate their commitment to eco-friendly practices, appealing to socially conscious consumers. This not only enhances brand reputation but also attracts customers who prioritize sustainability in their purchasing decisions, positioning businesses to thrive in a competitive environment.

Frequently Asked Questions

What are DTF transfers and how do they work?

DTF transfers, or Direct-to-Film transfers, are a modern printing technique that involves printing designs onto a film, which is then transferred to fabric via heat press. This method is known for its exceptional quality and versatility, making it suitable for various materials.

What are the advantages of DTF printing over traditional methods?

The advantages of DTF printing include superior image quality, durability, versatility across different fabric types, and cost-effectiveness for small production runs. Unlike traditional methods, DTF transfers resist fading and cracking, making them ideal for high-wear garments.

How does DTF compare to DTG printing?

DTF vs DTG printing highlights several differences: DTF transfers can be applied to a wider range of materials and are often more cost-effective, especially for small batches. In contrast, DTG is generally limited to cotton fabrics and may have higher setup costs.

Is DTF printing a cost-effective solution for small businesses?

Yes, DTF printing is highly cost-effective for small businesses, allowing for economical production runs with minimal setup costs. This makes DTF transfers a great option for those who need to produce custom apparel without significant investment.

What makes DTF transfers user-friendly for new printers?

DTF transfers are user-friendly due to their straightforward process. The steps involve printing onto film, applying adhesive powder, and using a heat press. This low learning curve makes it accessible for beginners and seasoned printers alike.

How does DTF printing contribute to eco-friendliness in garment production?

DTF printing helps reduce waste by using precise printing techniques that minimize excess inks and materials. This eco-friendly aspect appeals to businesses and consumers who are increasingly focused on sustainable production practices.

| Key Advantages of DTF Transfers | |

|---|---|

| Exceptional Quality and Detail | Produces sharp, vibrant designs with excellent color reproduction, ensuring complex patterns and logos are clearly captured. |

| Versatility in Material Compatibility | Works on various fabrics including cotton, polyester, and synthetics, making it suitable for diverse projects. |

| Durability of Prints | Resistant to cracking, fading, and peeling even after numerous washes, maintaining vibrancy over time. |

| Cost-Effectiveness | Allows for economical production runs, making it accessible for small businesses and individual creators. |

| User-Friendly Process | Streamlined process involving printing, applying adhesive, and heat transferring, suitable for both experienced and novice users. |

| Low Waste Production | Minimizes waste through precise printing, appealing to eco-conscious businesses and consumers. |

Summary

DTF transfers are revolutionizing the garment printing industry with their remarkable advantages. The transition to DTF provides exceptional quality, durability, cost-effectiveness, versatility, user-friendliness, and a commitment to low waste production. By adopting DTF transfers, businesses can enhance their operational qualities while meeting the demands of a diverse clientele. As the market continuously evolves, utilizing DTF technology may be the crucial enhancement your printing capabilities need. Embrace the innovative frontiers of printing with DTF transfers and unlock your full creative potential.