DTF transfers, or Direct-to-Film transfers, have quickly become a game changer in the custom apparel world. This innovative technique enables creators to effortlessly produce stunning, vibrant designs on various fabrics. If you’re looking to delve into DTF printing, understanding the intricacies of this method will significantly enhance your apparel printing experience. Beginners will find that DTF transfers offer flexibility and quality, making it an ideal choice for turning custom designs into reality. With the right tips and tricks, you can master the art of this heat transfer method and start your journey towards professional-grade creations.

Direct-to-Film transfers are not just reshaping the garment printing landscape; they represent a leap forward for artists and businesses alike. In essence, this printing technique involves transferring intricate images onto specially designed films before applying them to fabric. Known for their compatibility with diverse materials and vibrant color reproduction, these transfers have garnered attention among custom design enthusiasts. Alternative phrases like “heat transfer printing” or “film transfer technology” also speak to this exciting process that inspires many to explore personalized apparel creation. As we dive into the mechanics and benefits of DTF printing, you’ll discover effective strategies and beginner tips to set you up for success.

Understanding the Benefits of DTF Transfers in Custom Apparel

DTF transfers are heralded for their versatility in the printing industry, particularly in custom apparel. This method allows for intricate designs to be reproduced with stunning color fidelity on various materials. Unlike traditional methods such as screen printing, DTF printing offers the ability to create detailed patterns and vibrant colors without the extensive setup time or costs associated with screens. Beginners can quickly produce high-quality items, making DTF an attractive option for small businesses or personal projects.

Another significant benefit of DTF transfers is their durability. DTF prints withstand multiple washes, ensuring that the designs remain intact over time. This robustness is largely due to the exceptional bond formed between the adhesive powder and the fabric during the heat transfer process. As a result, apparel printed with DTF transfers can maintain their fresh appearance longer, allowing creators to confidently sell or wear their custom designs without the worry of premature fading or peeling.

Choosing the Right Equipment for DTF Printing

When it comes to embarking on your DTF printing journey, selecting the right equipment is crucial. A dedicated DTF printer is vital, as it plays a significant role in determining the overall quality of your prints. Brands like Epson offer reliable models tailored for DTF, ensuring that beginners and seasoned printers alike can achieve optimal results. Additionally, looking for printers that come with conversion kits can also be a wise investment, as they enable users to adapt existing machines for DTF use.

In addition to the printer, quality inks and heat presses are essential components of the DTF printing process. It’s important to invest in high-quality DTF inks that are designed specifically for this technique, as they provide vibrant colors and better adhesion. A heat press with consistent temperature control also matters greatly; the right settings ensure the transfer process occurs smoothly, promoting optimal results that elevate your custom designs.

Understanding Design Considerations for DTF Printing

Designing for DTF printing requires attention to detail and understanding of specific parameters to achieve the best results. For instance, utilizing the CMYK color mode is crucial as it aligns with how colors are processed in DTF transfers. This ensures that the final prints mirror the intended colors more closely, vibrant and true to life. Additionally, ensuring high-resolution images—at least 300 DPI—can make a significant difference, as lower resolutions may result in pixelation and poor print quality.

File formats also play a critical role in DTF printing success. Using software such as Adobe Illustrator or CorelDRAW, and saving files in formats like PNG or TIFF, ensures compatibility and helps to preserve the integrity of the design throughout the printing process. With these design considerations in mind, beginners can create customized artwork that not only looks aesthetically pleasing but also prints flawlessly on fabric.

Mastering the DTF Transfer Process for Beginners

The transfer process itself can determine the success of your DTF printing venture. First, pre-heating your fabric is a crucial step that can significantly affect adhesion. This brief exposure to heat removes moisture and prepares the surface, allowing for a stronger bond between the transfer and fabric. Following that, setting the transfer at the correct temperature range, typically between 300°F to 320°F, along with the appropriate pressure, is essential for a flawless application.

Timing is another vital aspect of the transfer process. Ideally, pressing should last about 10-15 seconds, though this may vary depending on the fabric type. Understanding the nuances of the transfer process not only enhances the durability of your prints but also ensures that your designs come out looking their best. By mastering these steps, beginners can produce professional-level apparel that delights customers and showcases their custom designs.

Post-Application Care for DTF Printed Apparel

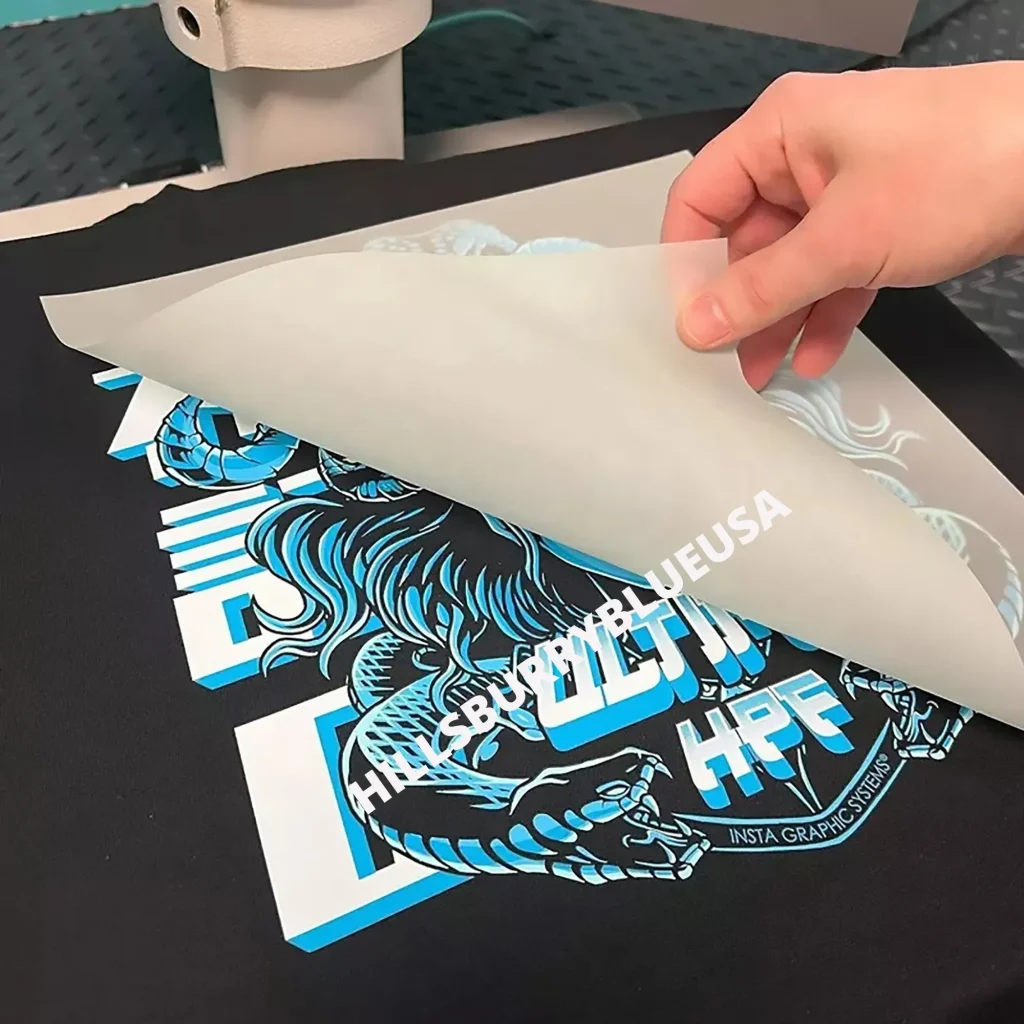

After completing the DTF transfer process, the way you care for your newly printed apparel plays a significant role in maintaining its quality. It’s essential to allow the printed items to cool before carefully peeling away the film. This practice not only helps prevent damage to the print but also ensures better adherence to the fabric. Once the film is removed, special attention should be given to how you wash the items.

To extend the lifespan of DTF printed designs, wash items inside out using cold water. This method protects the transfer from abrasive elements in the wash cycle and helps to preserve vibrant colors. Furthermore, avoiding the use of bleach and opting for gentle detergents can contribute to the longevity of your designs, keeping them looking fresh and new for a more extended period.

Connecting with DTF Printing Communities for Learning and Support

Engaging with communities focused on DTF printing is invaluable for beginners eager to refine their skills and broaden their understanding of the craft. Online forums, social media groups, and local meetups provide great platforms to share experiences, tips, and techniques among fellow printers. These interactions can offer insights from seasoned professionals, helping new printers avoid common pitfalls and accelerate their learning curves.

Participating in these community discussions can also keep you updated on the latest trends and innovations in the DTF market. With the continuous advancements in materials and equipment, being part of a network can help you learn about new suppliers, gain knowledge on the best practices, and discover resources that can enhance your printing journey. By fostering connections within the DTF printing community, you create opportunities for growth and creativity in your custom apparel projects.

Frequently Asked Questions

What are DTF transfers and how do they work?

DTF transfers, or Direct-to-Film transfers, involve printing designs onto a film before transferring them to fabric using heat. This method allows for high-quality, vibrant prints suitable for various materials, making it a popular choice in custom apparel printing.

What equipment do I need for DTF printing?

To start DTF printing, you will need a dedicated DTF printer, high-quality DTF inks, a reliable heat press, and specific DTF transfer films and adhesive powders. Investing in quality equipment is crucial for achieving the best results.

Can I use any printer for DTF transfers?

Not all printers are suitable for DTF transfers. It’s recommended to use specialized DTF printers or convert traditional inkjet printers like Epson models with conversion kits to ensure quality and compatibility with DTF printing technology.

How can I improve the quality of my DTF printed designs?

To enhance your DTF printed designs, use the CMYK color mode, ensure high resolution (at least 300 DPI), and save your files in formats like PNG or TIFF. These adjustments can significantly improve the sharpness and detail of your prints.

What are beginner tips for using DTF transfers?

Beginner tips for DTF transfers include practicing on small batches to refine your technique, preheating fabric before transfer, and washing finished items inside out in cold water to maintain print quality.

What care is needed after applying DTF transfers?

After applying DTF transfers, allow the fabric to cool before peeling off the film. For maintenance, wash your apparel inside out in cold water to prevent fading and extend the life of the design.

| Key Point | Details |

|---|---|

| Introduction to DTF Transfers | DTF transfers have transformed the custom apparel industry, enabling easy and vibrant fabric designs. |

| Understanding DTF Printing | Involves using a specialized printer to transfer designs onto fabric for high-quality products. |

| Choosing the Right Equipment | Invest in a dedicated DTF printer, quality inks, and a reliable heat press to ensure great results. |

| Quality Films and Powders | Select high-quality transfer films and adhesive powder for durable designs. |

| Design Considerations | Use CMYK color mode, high resolution images, and suitable file formats for optimal prints. |

| Printing Settings | Calibrate printer settings for color saturation and quality output. |

| The Transfer Process | Preheat fabric, apply transfer at the correct temperature, and adjust timing based on material. |

| Post-Application Care | Wash items inside out in cold water to protect the transfer. |

| Resources for Learning | Explore guides, dedicated websites, and tutorials to deepen knowledge on DTF printing. |

| Market Developments | Growing demand in custom apparel has led to more suppliers and resources for beginners. |

| Recommendations for Beginners | Practice on small batches and join online DTF communities for support and learning. |

Summary

DTF transfers have emerged as a game-changing technology in the custom apparel industry, offering unmatched versatility and quality. Embracing the tips and insights shared in this guide allows beginners to unlock their creative potential and efficiently produce stunning designs. By investing in the right equipment and materials, while also refining their techniques through practice and community engagement, individuals can fully harness the power of DTF transfers. Such practices not only enhance personal projects but also pave the way for entrepreneurial success in the competitive custom printing market.