DTF transfers, short for Direct to Film transfers, have revolutionized the landscape of DIY T-shirt printing, making it a favorite among creative individuals. With this innovative technique, stunning custom T-shirt designs can be achieved easily and affordably. Whether you are just a beginner or an experienced crafter, knowing how to use DTF transfers opens up a world of possibilities, allowing you to create vibrant and eye-catching designs. This method of heat transfer printing delivers exceptional print quality that adheres beautifully to various fabrics. Join the growing community of DIY enthusiasts and learn how DTF printing can enhance your custom apparel creations, bringing your artistic visions to life.

The world of Direct to Film printing, often referred to as DTF transfers, presents an exciting avenue for T-shirt creators. This method, which involves applying designs through a specialized transfer film, allows for intricate and vivid prints that stand out. As a user-friendly alternative to traditional printing techniques, such as screen printing, DTF provides a cost-effective solution for small batches and unique fabric applications. With its exceptional adaptability and quality, understanding the ins and outs of DTF transfers can vastly improve your skill set and enhance your DIY projects. Unleash your creativity and explore how this modern heat transfer technology can transform your T-shirt designs into wearable art.

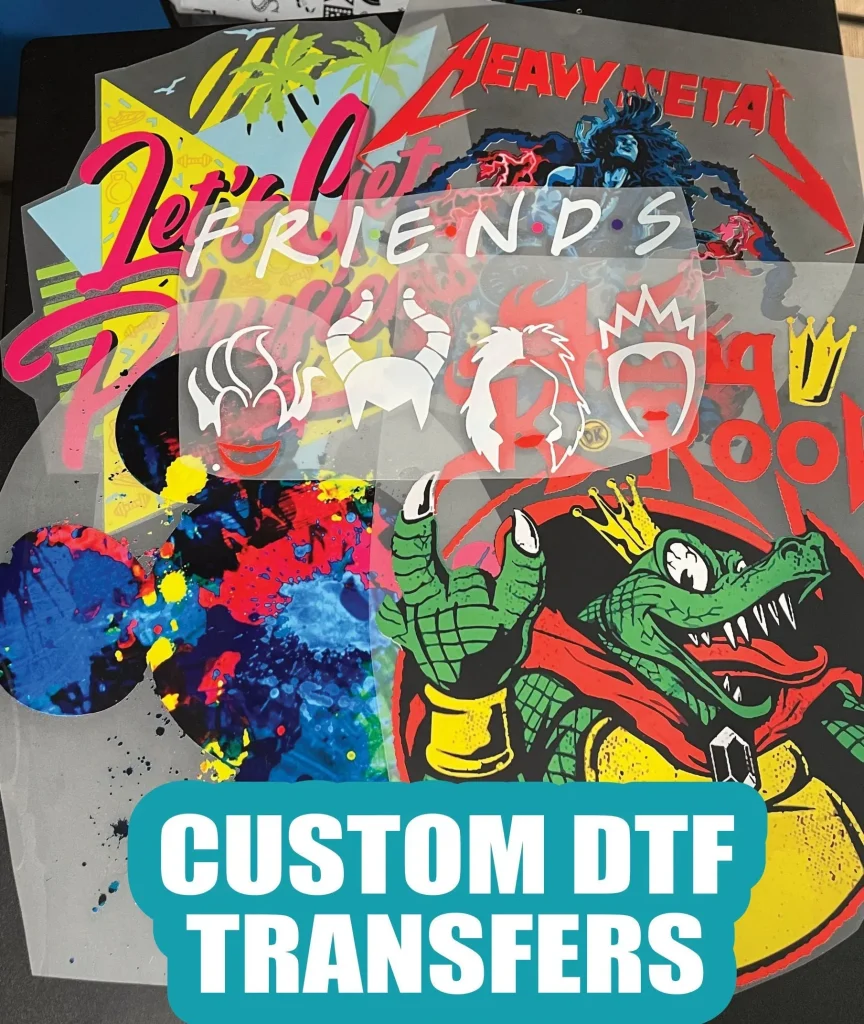

Understanding the Basics of DTF Transfer Printing

DTF (Direct to Film) transfer printing represents a new frontier in the world of DIY T-shirt customization. This method utilizes a high-quality printing process where designs are printed onto a film material using specialized inks. The process not only allows for vibrant colors but also captures intricate details, making it ideal for custom T-shirt designs. Unlike traditional methods such as screen printing, DTF printing offers versatility in design and fabric compatibility, including cotton and polyester blends.

Understanding how DTF transfers work is crucial for anyone looking to get into DIY T-shirt printing. The fundamental steps involve creating a digital design, printing it onto a transfer film, applying adhesive, and using heat to transfer the ink onto fabric. This method is user-friendly and doesn’t require a substantial investment in equipment, which makes it an attractive option for beginners wanting to learn how to use DTF transfers effectively.

As you dive deeper into DTF printing, it’s worth exploring the differences and benefits compared to other popular methods like heat transfer printing and screen printing. DTF excels in delivering prints with rich colors and precise detail, enabling crafters to experiment with different designs without the limitations typical of older techniques.

The rise of DTF technology offers DIY enthusiasts the chance to elevate their crafting projects significantly. With vital information at your fingertips, you can confidently embrace this innovative solution.

The Advantages of Using DTF Transfers for DIY Projects

The benefits of utilizing DTF transfers in your DIY T-shirt printing endeavors are manifold. Firstly, the quality provided by DTF printing is second to none. Unlike older techniques, DTF can produce detailed and vibrant images that remain crisp even after multiple washes. This durability makes it a smart choice for anyone looking to create long-lasting custom T-shirt designs.

Furthermore, DTF transfers are cost-effective, especially for small batch projects. As this technology becomes more accessible, crafters can avoid the high costs associated with bulk screen printing. DTF transfers allow for the production of one-off designs without sacrificing quality, so you can experiment with various artworks aptly without financial strain.

Besides being budget-friendly, DTF transfers are extremely user-friendly. There’s a minimal learning curve, making it suitable for beginners as well as seasoned printmakers. With the right instructions and access to quality materials, even novice crafters can produce professional-looking results.

This combination of high-quality output and ease of use makes DTF transfers an attractive option for enthusiasts of all skill levels, encouraging creativity and customization.

Getting Started with DTF Printing: A Step-by-Step Guide

If you’re ready to jump into DTF printing, the first step is to create your custom design using graphic design software. Programs like Adobe Illustrator or CorelDRAW offer powerful tools for crafting intricate designs that can be perfectly replicated in your T-shirt prints. Ensure your images are high-resolution and saved in RGB format to maintain quality during the printing process.

Once your design is ready, the main part begins—printing the transfer. Using a DTF printer, you’ll print onto specially coated transfer film. This process includes the use of vibrant, high-quality inks. After printing, applying the powder adhesive while the ink is wet is crucial; this step ensures your gel adheres to the fabric accurately. Following this, heat pressing the design onto your T-shirt will ultimately secure your artwork, making it a solid piece of wearable art.

Going through these steps methodically will not only ensure your projects turn out beautifully but will also help you gain confidence in your ability to utilize DTF transfers. Pay attention to the specifics, such as temperatures and timings during heat pressing, as they can significantly affect the final product.

As you familiarize yourself with the equipment and processes involved, you’ll find ample opportunities to innovate your techniques and experiment with custom designs.

Essential Tips for Successful DTF Transfers

To maximize your success with DTF transfers, there are a few tips you should keep in mind. Firstly, choosing the right fabric is vital; DTF transfers work exceptionally well on cotton and polyester blends. These materials absorb ink more effectively, leading to vibrant colors and images that last.

Another important factor is pre-washing your fabrics prior to applying transfers. This step helps eliminate any residues that could hinder the adhesive bond, ensuring cleaner and more durable results. Additionally, consider performing test prints with varying heat press settings to determine what works best with your specific equipment and fabric type. This experimentation can help optimize your setup and prevent potential pitfalls.

Remember, even the most experienced DTF printers began as novices. Don’t hesitate to learn from your experiences and adjust your techniques based on previous outcomes.

Arming yourself with these practical tips will enhance your DTF printing efforts, ultimately leading to more successful and satisfying DIY projects.

Exploring Recent Innovations in DTF Technology

DTF technology has seen significant advancements in recent years, making it even more appealing to DIY crafters and small businesses alike. New ink formulations promise increased durability and wash resistance, which are vital for maintaining the integrity of printed designs over time. These innovations mean that crafters can sell or wear their creations with the confidence that they will stand up to regular use.

Moreover, the introduction of compact, user-friendly DTF printing machines has made it more accessible than ever before. Many of these machines are designed for home use, helping hobbyists step into the world of custom T-shirt printing without needing a professional setup. As these technologies continue to evolve, it opens new doors for creativity and enterprise in the realm of DIY fashion.

Staying informed about recent developments can help you make the most of your DTF transfers, as new tools and techniques emerge that might further simplify the process or enhance the quality of your designs.

By keeping abreast of these changes, you’ll not only improve your craftsmanship but also maintain an edge in your DIY projects.

Resources for Mastering DTF Transfers

If you’re serious about mastering the art of DTF transfers, there are a multitude of resources you can tap into. Comprehensive online courses like CreativeLive’s ‘Beginner’s Guide to DTF Transfers’ provide systematic learning approaches, teaching you the basics to advanced techniques in an engaging format. This can be particularly useful for visual learners who benefit from seeing techniques demonstrated.

In addition to course offerings, industry-specific magazines, such as Printwear, regularly feature articles that discuss emerging trends and technology updates in DTF printing. By following their insights, you remain informed about the tools and materials that will benefit your projects.

Join forums or communities dedicated to DTF printing; sharing experiences and tips with peers will not only enhance your skills but also foster a sense of camaraderie within the crafting space. By actively engaging with these resources, you’ll continuously sharpen your skills and expand your creativity.

Leveraging these learning opportunities can provide the guidance needed to elevate your DTF printing expertise significantly.

Frequently Asked Questions

What are DTF transfers and how do they work for DIY T-shirt printing?

DTF transfers, or Direct to Film transfers, are a printing technique where designs are printed onto a specialized film. This film is then heat transferred onto various fabrics, creating vibrant and durable custom T-shirt designs. The process involves using a DTF printer, applying a powder adhesive, and using a heat press to bond the design to the fabric.

How do I create custom T-shirt designs using DTF transfers?

To create custom T-shirt designs with DTF transfers, first, use graphic design software to craft your artwork. Print this design on DTF transfer film with a DTF printer, apply a powder adhesive, and then heat press it onto your T-shirt. This method ensures high-quality prints that are perfect for DIY projects.

What materials work best with DTF printing for beginners?

For beginners using DTF printing, cotton and polyester blended fabrics yield the best results. These materials absorb ink effectively, showcasing the vibrant colors and fine details that DTF transfers are known for. Always pre-wash your fabrics to improve adhesion.

Is DTF printing expensive compared to other methods of heat transfer printing?

DTF printing is often more cost-effective for small runs or personal projects compared to traditional screen printing. This method requires less equipment and lower startup costs while still providing high-quality, custom T-shirt designs.

What are the key steps to use DTF transfers for T-shirt customization?

To use DTF transfers effectively, start by designing your artwork, then print it onto DTF film using a DTF printer. Apply adhesive powder to the wet ink, and finally, heat press the film onto your T-shirt to transfer the design. Peeling the film off reveals your custom design.

Are there any tips for achieving the best results with DTF transfers?

For optimal results with DTF transfers, ensure you use high-resolution designs, experiment with heat press settings, and pre-wash your fabrics. Using proper input materials will enhance durability and color vibrancy in your finished custom T-shirt designs.

| Key Points | Details |

|---|---|

| What Are DTF Transfers? | A printing process that transfers designs onto specialized film for application on fabrics using heat. |

| Key Advantages of DTF Transfers | 1. High Quality: Captures fine details and vibrant colors. 2. Cost-Effective: Affordable for personalized projects compared to traditional screen printing. 3. User-Friendly: Minimal equipment and training needed. |

| Steps to Use DTF Transfers | 1. Design Creation: Use graphic design software. 2. Print the Transfer: Use a DTF printer with specialty inks. 3. Apply Powder Adhesive: Crucial for bonding. 4. Heat Pressing: Apply heat to transfer design. 5. Peeling and Finishing: Remove film and improve durability. |

| Tips for Best Results | – Use cotton and polyester blends for best results. – Pre-wash fabrics for better adhesion. – Experiment with heat settings for optimal results. |

| Recent Developments | In 2024, advancements include improved ink formulations and new machines making DTF printing more accessible. |

| Resources for Learning More | – CreativeLive’s “Beginner’s Guide to DTF Transfers” – Printwear Magazine’s “DTF Transfers: The Future of Custom T-Shirts” |

Summary

DTF transfers represent a groundbreaking advancement in the world of DIY T-shirt customization. With its user-friendly process and the ability to produce high-quality, vibrant designs, DTF transfers have become the go-to choice for crafters and enthusiasts alike. As technology evolves, the ease and accessibility of DTF transfers continue to open new avenues for creativity, allowing anyone to craft unique, personalized T-shirts. By following the steps outlined in this guide, utilizing the recommended tips, and exploring educational resources, you can unlock the full potential of DTF transfers and elevate your DIY projects to stunning new heights. Happy crafting!