DTF transfers, or Direct-To-Film transfers, are revolutionizing the custom apparel printing industry by offering a unique blend of versatility and high-quality output. Unlike traditional printing methods such as DTG (Direct-To-Garment) or screen printing, DTF printing enables designers to achieve vibrant colors and intricate details on a diverse range of fabrics. This method not only excels in creating eye-catching designs but also ensures long-lasting durability, making it an appealing choice for businesses aiming for longevity in their apparel products. As the demand for personalized clothing rises, DTF transfers stand out as a highly efficient and cost-effective solution. In this article, we delve into the various advantages of DTF printing compared to its counterparts, including sublimation printing, and provide insights into why it’s becoming the go-to choice for custom apparel.

The emergence of Direct-To-Film or DTF technology represents a significant advancement in the landscape of textile printing. Often regarded as a game changer, DTF is a versatile printing solution that caters to the needs of businesses seeking to produce high-quality apparel. This innovative technique is capable of handling a variety of materials, distinguishing it from options like DTG and sublimation, which have more limitations. Moreover, DTF printing offers a distinct advantage with its ability to deliver vibrant and durable prints that do not fade easily, setting a new standard for custom garment production. By exploring this printing technique, we open a dialogue about its impact and the advantages it holds over other popular methods like screen printing and DTG.

Understanding DTF Transfers: A Game Changer in Apparel Printing

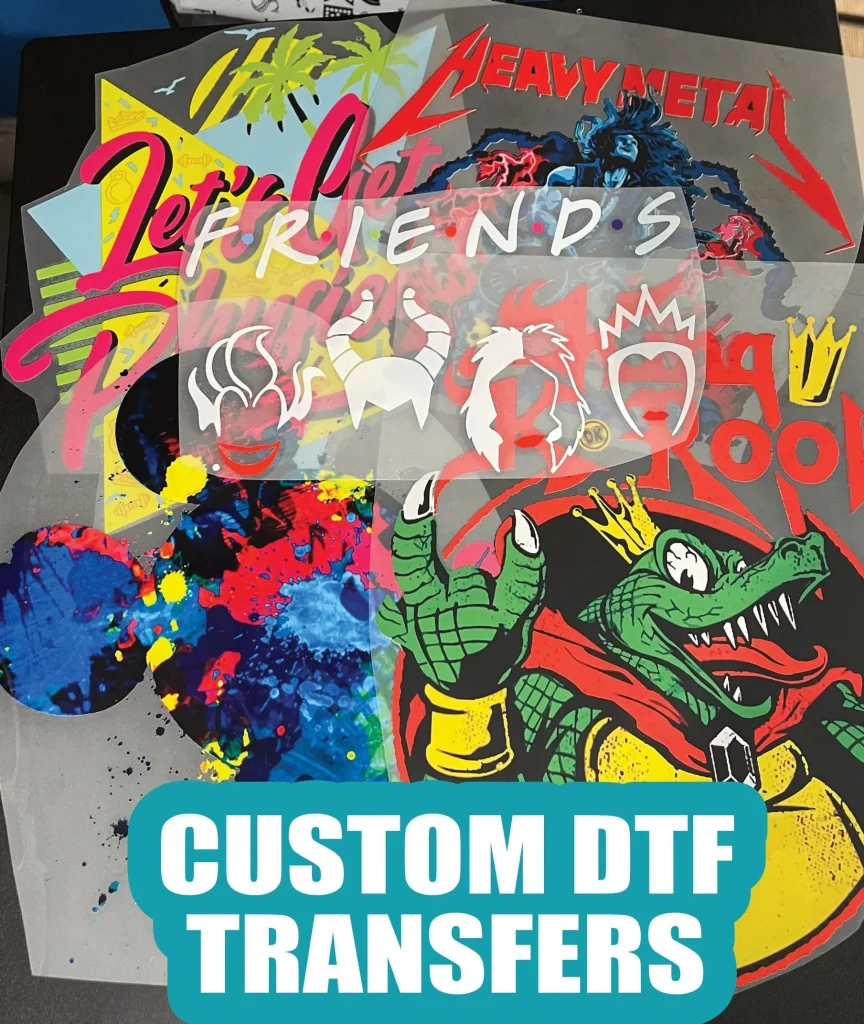

Direct-To-Film (DTF) transfers have revolutionized the world of custom apparel printing by offering an effective solution for both small and large-scale productions. The process involves printing intricate designs onto a special film, which can then be transferred onto various garment types using heat and pressure. Unlike traditional methods like screen printing or DTG, which have specific limitations, DTF’s versatility allows for application on a wide array of fabrics including cotton, polyester, and blended materials, making it a favored choice for custom designs.

One of the most appealing aspects of DTF transfers is their ability to produce high-quality and vibrant colors that stand out impressively on any fabric. This quality is particularly crucial for businesses specializing in custom apparel, where eye-catching designs can significantly impact consumer interest. Furthermore, the durability of the DTF prints ensures that clothing maintains its vibrancy and quality even after numerous washes, providing a long-lasting product that customers will love.

DTF Printing vs. DTG Printing: Which Is Better for Your Business?

When comparing DTF printing with Direct-To-Garment (DTG) printing, it’s essential to consider the differences in quality and material compatibility. DTG is known for its precision, particularly for detailed designs and fine artwork. However, DTF printing typically delivers richer colors and better coverage on dark fabrics, allowing for a broader range of design possibilities. This aspect makes DTF suitable for various applications, from fashion apparel to promotional items, whereas DTG is limited mainly to lighter, more specific fabrics.

Moreover, the cost implications of each method play a significant role in the decision-making process for many businesses. DTF printing often presents a lower barrier to entry in terms of equipment costs and setup time, making it an attractive option for smaller custom print shops or start-ups. In contrast, DTG printers can be more expensive and require more maintenance, leading to higher operational costs over time.

Comparative Analysis: DTF vs. Screen Printing for Custom Designs

Screen printing has long been a staple in the custom apparel industry due to its efficiency in bulk production. However, DTF printing is making significant inroads by offering quicker setup times and greater flexibility, particularly for smaller orders or designs with multiple colors. Unlike screen printing, which can be costly and time-consuming for intricate designs, DTF allows for rapid production, making it perfect for businesses looking to meet the fast-paced demands of today’s market.

Durability is a critical factor in any printing method, and both DTF and screen printing boast their strengths in this area. While screen printing uses thicker ink layers that generally enhance longevity, DTF prints also offer impressive durability and resistance to wear and tear. This factor is particularly beneficial for apparel intended for repeated use, satisfying customers’ expectations for high-quality, lasting designs.

Sublimation vs. DTF: Color Vibrancy and Material Versatility

While sublimation printing is celebrated for its vibrant color output, it has significant limitations that DTF printing overcomes. Sublimation is restricted to polyester fabrics and tends to excel primarily in all-over prints. In contrast, DTF printing can be applied to a wider range of materials, including cotton and blends, opening up new avenues for creative expression in design. This versatility makes DTF a more adaptable solution for businesses aiming to cater to diverse fashion needs.

Additionally, DTF delivers robust color quality across various substrates, ensuring that designs do not fade quickly and maintain their brilliance over time. This feature is particularly important in custom apparel, where the first impression can have a lasting impact on customers. By choosing DTF, businesses can ensure that their products stand out in a crowded market while also appealing to customers who value durability and quality.

With advancements in technology driving new developments in DTF, businesses are now equipped to produce high-quality graphics that rival that of sublimation without being limited by fabric choice.

Recent Advancements in DTF Technology: Innovations Driving Growth

As of 2023, the DTF printing industry has seen remarkable advancements that continue to enhance the quality and user-friendliness of the technology. Improved formulations for inks and films have emerged, offering better adhesion to fabrics and creating softer feels, which is crucial for customer satisfaction. These innovations empower businesses to produce high-quality printed apparel that resonates with consumers seeking comfort and style.

Moreover, new DTF printers have become increasingly compact and user-friendly, making this cutting-edge technology accessible even for smaller businesses that may not have previously been able to afford such advanced solutions. With resources and educational materials now widely available, including webinars that explore DTF production best practices, more entrepreneurs are embracing this technology to enhance their product offerings.

The Future of Custom Apparel Printing: Exploring DTF’s Role

Looking ahead, it’s clear that DTF printing will play a pivotal role in the evolution of custom apparel printing. Its combination of versatility, color quality, and durability positions it as a top choice among various printing methods. As more businesses adopt DTF technology, we can anticipate ongoing improvements, such as enhanced print capabilities and reductions in operational costs, making it an even more attractive option for global apparel markets.

The expansion of DTF capabilities will likely lead to new creative avenues for designers and business owners alike. With the ability to print on a wide range of materials and produce vibrant designs, DTF printing not only meets market demands but also inspires innovation within the fashion industry. Thus, businesses looking to stay ahead of the curve should consider integrating DTF into their production processes to capitalize on its growth trajectory.

Frequently Asked Questions

What are the advantages of DTF transfers compared to DTG printing?

DTF transfers offer richer colors and superior coverage, especially on dark fabrics, compared to DTG printing. Moreover, DTF is compatible with various materials beyond 100% cotton, making it a versatile choice for custom apparel.

How do DTF transfers stack up against screen printing?

While both DTF transfers and screen printing provide excellent durability, DTF printing boasts quicker setup times, making it ideal for short-run jobs or colorful designs. Screen printing may be more economical for large orders due to its efficiency in bulk production.

What types of fabrics can DTF transfers be applied to?

DTF transfers are remarkably versatile and can be used on a wide range of fabrics, including cotton, polyester, and their blends—making them suitable for various custom apparel needs.

Can DTF printing deliver vibrant colors like sublimation printing?

Yes, DTF printing produces vibrant and bright colors that stand out on numerous fabric types. While sublimation is limited to polyester and excels in all-over prints, DTF maintains high color quality across multiple textiles.

Is DTF printing cost-effective for small businesses?

DTF printing presents a lower barrier to entry compared to other techniques like DTG, making it particularly attractive for small custom print shops due to its affordable startup costs and equipment.

How has DTF printing technology improved in recent years?

Recent advancements in DTF printing include improved inks and transfer films that enhance print quality, as well as user-friendly equipment that makes it accessible for small businesses, driving wider adoption in the market.

| Comparison Factor | DTF Printing | DTG Printing | Screen Printing | Sublimation |

|---|---|---|---|---|

| Quality & Color | Vibrant colors, better coverage, especially on dark fabrics. | More suited for intricate designs. | Economical for large orders due to bulk efficiency. | Excels in all-over prints, limited to polyester. |

| Material Compatibility | Works on cotton, polyester, and blends. | Best on 100% cotton materials. | Good for various materials, but requires thicker ink. | Limited to polyester, cannot print on dark colors. |

| Cost & Setup | Lower barrier to entry for businesses. | Higher startup costs for equipment. | Labor-intensive setup; better for large jobs. | Not suitable for varied material types. |

| Durability | High durability, withstands numerous washes. | Suitable for intricate details, but less durable overall. | Very durable but thicker ink can affect texture. | Color fastness is high, but limited to fabric types. |

Summary

DTF Transfers represent a groundbreaking advancement in the field of custom printing, particularly in apparel and textiles. This innovative method stands out for its remarkable versatility, durability, and vibrant color reproduction, making it a preferred choice for a wide range of businesses. As more companies seek quality and efficiency in their printing solutions, DTF Transfers are set to play a significant role in the future of the printing industry, particularly given its lower startup costs compared to other methods. With ongoing technological improvements and increased accessibility, DTF continues to gain traction, ensuring it meets the ever-evolving demands of consumers.