The DTF Gangsheet Builder is an essential tool for anyone looking to excel in the world of DTF (Direct-to-Film) printing. This innovative platform streamlines the process of designing DTF prints by allowing users to optimize gang sheets for efficiency and creativity. With the right tips for DTF printing and effective design preparation, creators can maximize their print quality while minimizing waste. By understanding the heat transfer process involved, users can ensure their designs boast vibrant colors and intricate details that truly stand out on fabric. Join us as we explore the nuances of using the DTF Gangsheet Builder to elevate your custom apparel and redefine your printing capabilities.

In the realm of custom fabric printing, crafting effective gang sheets is essential for streamlining production. The gang sheet technique allows multiple designs to be combined on a single film sheet, making it a cost-effective strategy for those in the DTF printing industry. Utilizing smart design preparation and understanding essential tips on DTF printing can significantly enhance the efficiency of the heat transfer process. This creative approach not only reduces material waste but also provides unique opportunities for designing standout prints that cater to various fabric types. Let’s delve deeper into these methods and optimize your DTF design workflow.

Mastering DTF Printing Techniques

DTF printing has revolutionized the way custom designs are applied to fabric, blending creativity and efficiency unlike any other printing method. By using Direct-to-Film technology, designers can achieve stunning results with vibrant colors and intricate details. To truly master DTF printing, it’s essential to familiarize yourself with the various techniques that can significantly improve the output quality. From selecting the right films to optimizing ink usage, understanding these techniques can elevate your projects to a professional standard.

One key aspect to consider is the heat transfer process involved in DTF printing. Unlike traditional methods where direct contact with the heat source is necessary, DTF allows the design to be transferred via a film. This results in less risk of the fabric being damaged or the design fading. Additionally, experimenting with different temperature settings and press times can yield better results, ensuring designs adhere perfectly while maintaining their vibrancy.

Essential Tips for DTF Gang Sheet Preparation

Preparing your designs for DTF gang sheets is crucial for achieving optimal print quality and minimizing waste. One of the fundamental steps is ensuring your images are high resolution. When you use low-quality images, the final print can suffer from pixelation, impacting the overall vibrancy of the colors. Aim for a minimum of 300 dpi for your designs, as this provides the clarity necessary for professional results.

Moreover, understanding color settings for different fabrics is paramount in DTF design preparation. Light fabrics might require adjustments in color vibrancy compared to dark materials, ensuring that the final product pops regardless of the background. By tailoring your designs based on these factors, you enhance the aesthetic appeal of your prints and maintain consistency across various fabric types.

Optimizing DTF Print Settings

Choosing the right printer settings is vital for successful DTF printing results. Utilizing compatible DTF inks is essential to achieving the desired adhesion and vibrancy of colors on the transfer film. It’s crucial to set the printer to at least 1200 DPI to ensure fine details are captured in your designs. This high resolution is particularly important for intricate patterns and vibrant color applications.

Adjusting the printer’s color profile settings based on the media and ink type used can also significantly affect the final output. This ensures that colors are rendered accurately, enhancing the aesthetic value of your designs. Neglecting this step could result in dull prints that don’t reflect the original design, which can be frustrating for both designers and consumers alike.

Post-Processing Techniques for DTF Printing

Post-processing is a vital step in DTF printing that can enhance the durability and quality of your final prints. Once the design is transferred, allowing it to cool completely before peeling away the film is crucial. This avoids any potential damage to the design, ensuring that the ink adheres properly to the fabric.

Additionally, performing a second heat press after peeling can reinforce the bond between the design and fabric. This step not only contributes to the longevity of the print but also helps prevent issues like cracking or peeling over time. By incorporating these post-processing techniques, you ensure your DTF gang sheets not only look stunning but also withstand the rigors of wear and washing.

Maintaining Your DTF Printing Equipment

Proper maintenance of your DTF printing equipment is essential for achieving consistent high-quality prints. Regular cleaning of printer heads is crucial to prevent issues such as ink clogging, which can affect print quality. Establishing a routine helps ensure that you catch any potential problems before they escalate, maintaining smooth operation.

Furthermore, monitoring your supplies, including DTF film, adhesive powder, and ink, is vital. Always have a consistent supply on hand to prevent interruptions during production. This not only streamlines your workflow but also guarantees that you can meet your printing demands without delays, ultimately enhancing your business efficiency.

Exploring DTF Design Flexibility

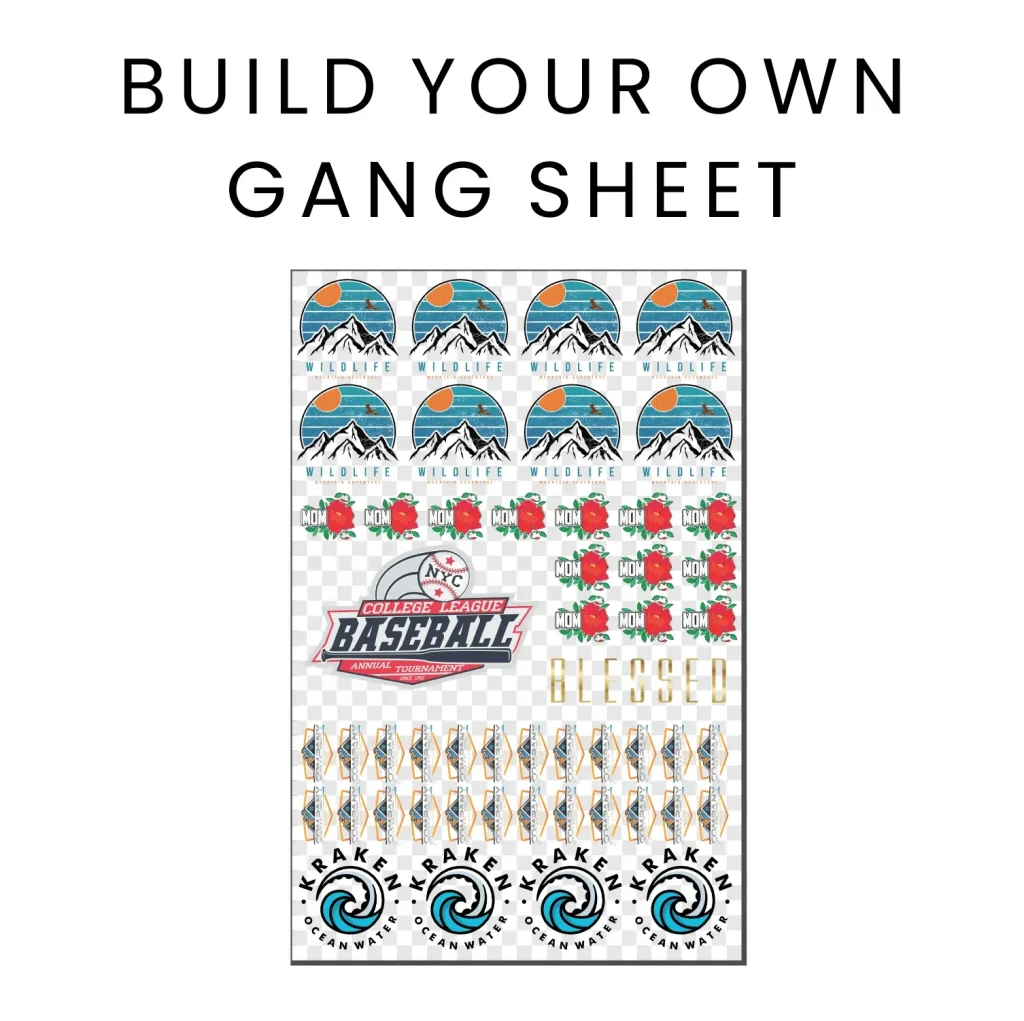

The flexibility that DTF printing offers can be a game-changer in the realm of apparel design. One of the significant advantages of using DTF gang sheets is the ability to combine various designs on a single sheet for printing. This not only optimizes material usage but also allows designers to experiment with different styles and color combinations without the traditional restrictions imposed by screen printing methods.

By utilizing this capability, designers can cater to diverse customer preferences and trends, creating a wider range of products that stand out in a competitive market. Engaging in creative experimentation with fonts, graphics, and layouts on gang sheets can lead to unique offerings that appeal to a broader audience, thereby enhancing marketability.

Frequently Asked Questions

What is a DTF Gangsheet Builder and how does it improve DTF printing processes?

A DTF Gangsheet Builder is a tool or process used to optimize multiple designs on a single sheet for DTF printing. It enhances efficiency by reducing material waste and production time while allowing for creative flexibility in designing DTF prints.

What are essential DTF printing tips for designing DTF prints?

Key DTF printing tips include using high-resolution images, adjusting color settings to CMYK for print accuracy, and ensuring that designs are optimized for the type of fabric being printed on, whether light or dark.

How do you prepare designs for effective use in a DTF gang sheet?

Preparing designs for a DTF gang sheet involves starting with high-resolution images, selecting proper color settings, and ensuring compatibility of design elements for different fabrics to achieve optimal results during the heat transfer process.

What steps should be taken during the heat transfer process for DTF gang sheets?

During the heat transfer process, apply hot melt powder adhesive immediately after printing while the ink is still wet. Cure the design at the correct temperature (160-180°C) for 15-20 seconds to ensure successful adhesion.

What post-processing tips can enhance the durability of designs printed with a DTF Gangsheet Builder?

To enhance durability, allow the transfer to cool completely before peeling the film. Furthermore, it’s advisable to heat press the design again post-peeling to ensure the strongest adhesion and longevity of the print.

How does using DTF gang sheets reduce waste and improve cost efficiency in printing?

Using DTF gang sheets reduces waste by allowing multiple designs to be printed simultaneously on one sheet, leading to lower material consumption and operational costs. This maximizes productivity and minimizes the time required for production.

| Key Points | Details |

|---|---|

| Understanding DTF Printing | DTF is a method that transfers designs onto fabrics using a special film, allowing vibrant colors on various materials. |

| Benefits of DTF Gang Sheets | Cost-effective, time-efficient, offers design flexibility, and reduces waste. |

| Preparing Your Designs | Use high-resolution images, correct color settings (CMYK for print), and tailor designs for fabric types. |

| Optimizing Print Settings | Select compatible DTF inks, a resolution of at least 1200 DPI, and adjust color profiles. |

| Printing Process | Apply adhesive while ink is wet, cure with heat press at the correct temperature and timing. |

| Post-Processing Tips | Allow cooling before peeling film and re-heat press for durability. |

| Maintenance of DTF Equipment | Regular cleaning of printer heads and consistent check on supplies are crucial. |

Summary

DTF Gangsheet Builder is an essential tool for those looking to elevate their custom apparel designs with efficiency and creativity. With a deep understanding of DTF printing, designers can maximize their potential by utilizing gang sheets that consolidate multiple designs, reducing waste and costs. This guide offers valuable insights into preparation, optimal printing settings, and maintenance tips necessary for achieving high-quality outputs. As you explore the world of DTF printing, remember to continually refine your techniques, experiment with innovative designs, and engage with community resources to enhance your skills. The journey to mastering DTF gang sheets will surely unlock a realm of possibilities in the fabric printing industry!