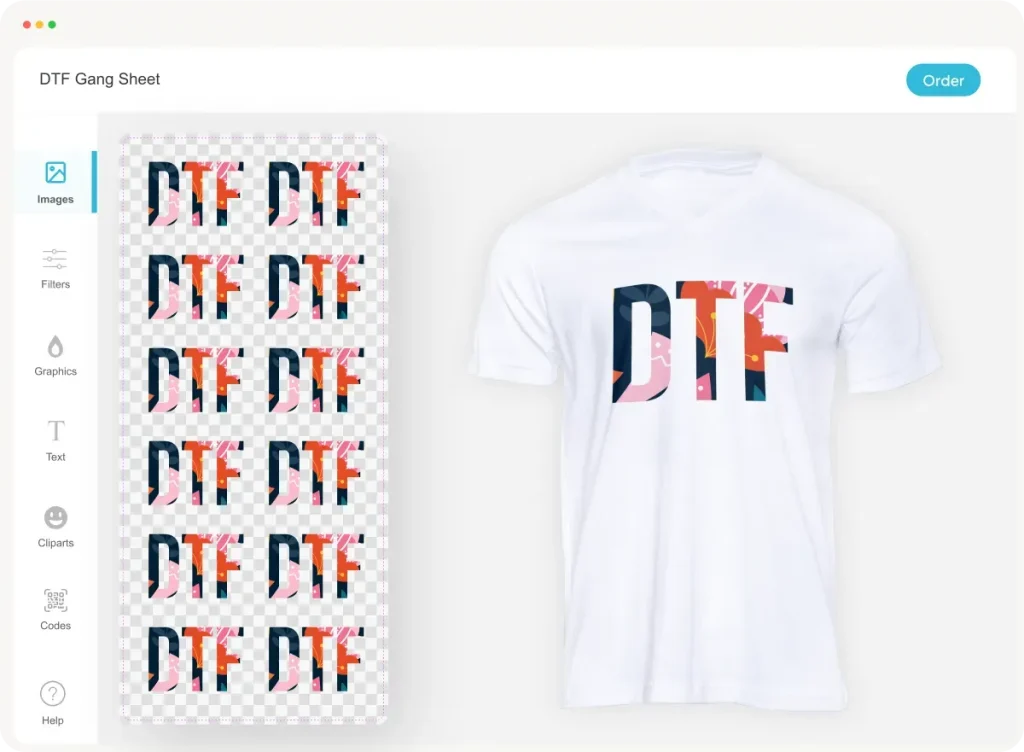

In the rapidly evolving world of printing, the **DTF gangsheet builder** has emerged as a game-changing tool for businesses. Leveraging **DTF printing** technology, this innovative method combines multiple designs into a single sheet, greatly enhancing efficiency and reducing costs. It allows printers to optimize their printing process while maximizing material usage, ultimately resulting in higher-quality outputs. Particularly beneficial for small to medium-sized enterprises, the DTF gangsheet builder not only streamlines production but also supports **sustainable printing methods**, appealing to environmentally-conscious consumers. By embracing this technology, businesses can stay ahead of competitors in the realm of **custom fabric printing** and improve their operational performance.

The concept of a **DTF gangsheet builder** refers to a specialized tool utilized for creating layouts that incorporate various designs on a single printable film. This technique harnesses the strengths of **gangsheet printing**, leading to considerable advantages in production efficiency and cost reduction. With the rise of personalized design requests in **custom fabric printing**, this approach enables businesses to cater to diverse customer needs while optimizing their resources. Furthermore, it aligns with contemporary trends towards **printing process optimization**, where sustainability and reduced material waste play a pivotal role. As the demand for innovative printing solutions grows, understanding these alternative terms and their implications can significantly benefit those in the printing industry.

Cost Efficiency in DTF Printing

The cost efficiency offered by a DTF gangsheet builder is nothing short of transformative for printing businesses. By allowing multiple designs to be printed simultaneously on a single sheet, this method reduces the amount of ink consumed significantly. This is particularly crucial for smaller printing firms that operate on tight margins and are always on the lookout for ways to cut costs without compromising on quality. Not only does this method lower ink and material costs, but it also allows businesses to pass on these savings to their customers, making the service more competitive in the increasingly saturated printing market.

In addition to reduced ink consumption, the gangsheet approach minimizes the waste of film. Instead of printing each design individually, the builder maximizes every inch of the sheet, ensuring that resources are used to their fullest potential. This rationalization of materials not only decreases production costs in the short term but also aids in inventory management. Print service providers can maintain a leaner inventory, reducing storage costs and addressing cash flow issues that often arise from surplus materials.

Time Savings with DTF Gangsheet Builders

One of the most prominent advantages of utilizing a DTF gangsheet builder is the substantial time savings that it renders to the printing process. By grouping several designs on a single sheet, the time spent on setup and execution is drastically reduced. Printers can prepare larger batches of designs simultaneously, which is especially beneficial for businesses that thrive on quick turnarounds—such as those in custom apparel and merchandise industries. The efficiency gained here translates directly into increased productivity and revenue potential.

Moreover, this optimization of the printing process allows businesses to handle larger orders with ease. Rapid production is essential in meeting tight deadlines, and by streamlining operations through a gangsheet builder, print service providers can deliver high-quality outputs without the usual bottlenecks. This ability to accommodate high-volume work ensures businesses remain flexible and responsive to market demands.

Design Flexibility in Custom Fabric Printing

The design flexibility afforded by DTF gangsheet builders is a game-changer for creative professionals within the custom fabric printing sector. This system allows designers to combine a variety of graphics, logos, and color schemes on the same sheet, elevating their creative possibilities. Designers can modify their approaches to meet client requests for personalized prints, ensuring that the end products are uniquely tailored to customer specifications and preferences.

Being able to mix and match designs on one sheet not only enhances the creative freedom of designers but also expands the market opportunities for print service providers. This capability can help businesses cater to niche markets that demand specific, customized solutions, thus broadening their customer base and increasing overall profitability. As clients seek more personalized services, having the flexibility to offer diverse printing options becomes crucial.

Increased Production Capacity through Optimization

Implementing a DTF gangsheet builder significantly enhances production capacity by optimizing the usage of film and materials. This technique ensures that the entire printable area is utilized efficiently, allowing for the production of a greater number of items in a single run compared to traditional methods. As noted in industry analyses, businesses that adopt such advancements can tackle larger orders effectively without compromising the quality of the prints.

Additionally, increased production capacity translates into higher output rates, which can lead to improved customer satisfaction. When a business is able to consistently deliver products faster, it gains a reputation for reliability and efficiency. This is particularly important in the competitive landscape of textile printing, where customer expectations are high and speed can be a determining factor in securing repeat business.

Sustainability in Printing Practices

In an era where sustainability is becoming a key concern for consumers, the DTF gangsheet builder stands out as a method that promotes eco-friendly practices in the printing industry. By significantly reducing material waste and optimizing ink usage, businesses that adopt this technology can align themselves with sustainable objectives, fulfilling growing consumer demands for responsible printing solutions. Implementing such eco-conscious methods not only enhances a brand’s image but also opens opportunities for collaboration with businesses that prioritize sustainability.

Moreover, adopting sustainable printing practices can provide a competitive edge. Research indicates that consumers are increasingly willing to choose brands that demonstrate a commitment to environmentally friendly operations. By integrating DTF gangsheet builders into production processes, print service providers can effectively showcase their dedication to sustainability, consequently attracting clients who value eco-friendly practices.

Recent Trends in DTF Printing Technology

Recent advancements in DTF printing technology invite businesses to stay abreast of trends that continue to shape the industry. With improvements in ink formulations and machine efficiencies, the capabilities of DTF gangsheet builders are becoming even more impressive. These upgrades can result in higher quality prints with richer colors and greater durability, further solidifying the position of DTF printing in textile applications.

As innovations unfold, it is vital for print service providers to adapt to these changes proactively. Keeping pace with technological advancements ensures that businesses can leverage DTF technology to its fullest potential, enabling them to enhance operational efficiency, reduce costs, and maintain a competitive stance within the market. Continuous learning and adaptation to current trends is essential for success in the dynamic world of custom fabric printing.

Frequently Asked Questions

What is a DTF gangsheet builder and how does it work?

A DTF gangsheet builder is a tool used in Direct-to-Film (DTF) printing that allows multiple designs to be printed on a single sheet of film. This process involves transferring vibrant inks onto specially coated film, which is then heat-pressed onto fabric. By utilizing a gangsheet builder, printers can optimize their production workflow, reduce ink wastage, and create high-quality prints efficiently.

What are the gangsheet printing advantages of using a DTF gangsheet builder?

The key advantages of gangsheet printing with a DTF gangsheet builder include cost efficiency, as multiple designs are printed concurrently, reducing material expenses. Additionally, it saves time by streamlining the print setup process. This method also enhances design flexibility, allowing for creative combinations, and increases overall production capacity to meet high demand.

How does DTF printing differ from traditional printing methods?

DTF printing differs from traditional printing methods by transferring ink onto a coated film first, rather than directly onto the fabric. This technique allows for higher-quality prints, greater color vibrancy, and the ability to print on various fabrics. A DTF gangsheet builder maximizes these benefits by enabling multiple designs to be printed and transferred at once, optimizing efficiency.

Can a DTF gangsheet builder contribute to sustainable printing methods?

Yes, a DTF gangsheet builder can significantly contribute to sustainable printing methods. By reducing material waste through the efficient arrangement of designs on a single sheet and minimizing ink usage, printers can adopt eco-friendly practices. This supports a growing trend among consumers who prioritize sustainability in their purchasing decisions.

How can a DTF gangsheet builder improve custom fabric printing services?

A DTF gangsheet builder enhances custom fabric printing services by allowing print providers to create unique designs tailored to customer requests. It supports the simultaneous printing of different graphics or logos on a single sheet, facilitating greater design variety. This flexibility helps businesses cater to diverse clientele and expand their service offerings effectively.

What trends are emerging in the DTF printing industry regarding gangsheet builders?

Recent trends in the DTF printing industry indicate advancements in ink formulations and machine efficiency, bolstering the use of DTF gangsheet builders. These developments not only improve operational efficiency but also enhance print quality, enabling businesses to meet the increasing demand for high-quality, customized prints while keeping up with market innovations.

| Key Point | Description |

|---|---|

| Cost Efficiency | Reduces operational costs by maximizing ink and material use through multiple designs on one sheet. |

| Time Savings | Streamlines the printing process, allowing for batch production and faster turnarounds. |

| Design Flexibility | Enables mixing of graphics and text on one sheet, catering to unique customer requests. |

| Increased Production Capacity | Allows printing of larger volumes and handling of high-demand orders without compromising quality. |

| Sustainability | Promotes eco-friendly practices by reducing waste and ink usage, appealing to environmentally-conscious consumers. |

Summary

The DTF gangsheet builder is revolutionizing the printing process by offering remarkable benefits that modern print businesses cannot afford to overlook. From significant cost benefits resulting in lower operational expenses to enhanced productivity through streamlined processes, the DTF gangsheet builder serves as an invaluable asset for those in the industry. Companies adopting this innovative technology benefit not only from increased production capacity and creative design flexibility but also contribute to sustainability efforts by reducing waste. As the landscape of printing evolves, integrating a DTF gangsheet builder can set businesses apart in a competitive market, ensuring they meet the growing demands for customized, high-quality printing solutions effectively.