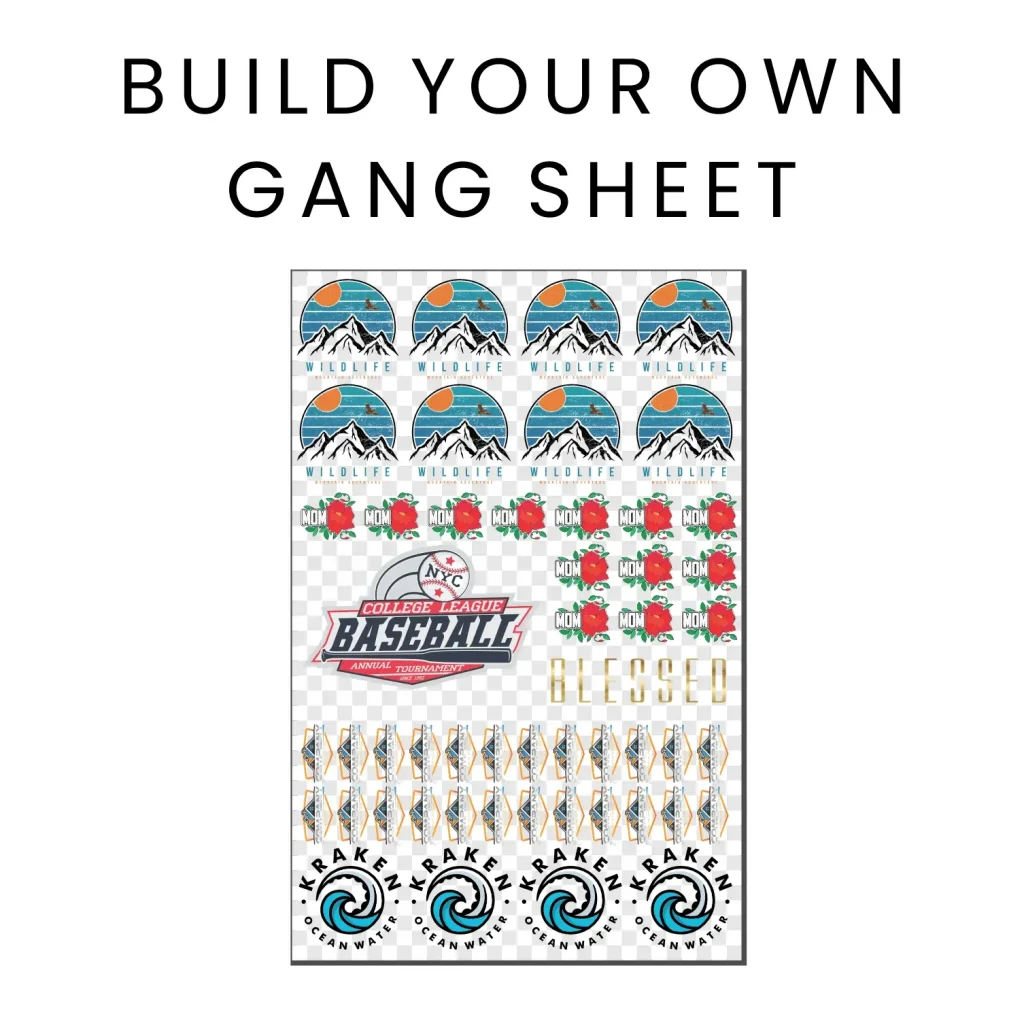

The DTF Gangsheet Builder is revolutionizing the way designers approach fabric printing, making it easier than ever to create vibrant and intricate designs. As part of the Direct-to-Film (DTF) printing technique, this innovative tool allows users to optimize their gang sheet design, enabling multiple graphics to be printed simultaneously. This comprehensive DTF printing tutorial will delve into various fabric printing techniques, guiding both beginners and seasoned practitioners on how to effectively utilize the DTF Gangsheet Builder. By harnessing these techniques, you’ll be able to enhance your print quality while drastically reducing waste, making it a cost-effective choice for custom apparel production. Get ready to transform your creative workflow and produce stunning printed designs with the ease that DTF offers.

Exploring the capabilities of the DTF Gangsheet Builder can significantly enhance your understanding of direct-to-film printing, a modern approach to transferring designs onto textiles. This method not only streamlines the design process through efficient gang sheet layouts but also promotes high-quality output across a variety of fabric types. Whether you’re interested in fabric printing techniques or searching for how to use DTF effectively, the advantages are numerous. By learning the nuances and best practices of this innovative printing solution, you can elevate your design work and meet the evolving demands of today’s market. This introduction reveals the potential of using DTF as a powerful tool for both creative expression and business success.

Understanding the DTF Printing Process

Direct-to-Film (DTF) printing is rapidly transforming the fabric printing landscape, distinguished by its simplicity and high-quality output. In contrast to traditional methods that may rely on extensive setup and preparation, DTF requires only a few critical components: a high-quality DTF printer, suitable transfer films, and specialized adhesive powders. The essence of this process lies in its ability to produce vibrant, detailed prints on diverse fabric types, ranging from cotton to polyester blends. This flexibility allows designers to cater to a wide variety of applications, whether for customized apparel or promotional items.

Understanding the DTF printing process starts with the essential technique of applying heat and pressure to transfer the design onto the fabric. The unique aspect of DTF is that it utilizes a film that captures intricate details and rich colors, ensuring that each design thrives even on complex patterns. Additionally, the final output is robust, facilitating washing and wear without significant fading or deterioration. This quality makes DTF printing a preferred choice among those seeking durable printing solutions.

Frequently Asked Questions

What is a DTF Gangsheet Builder and how does it work?

A DTF Gangsheet Builder is a tool used in Direct-to-Film (DTF) printing to arrange multiple designs on a single transfer sheet. This optimization helps save material and production costs while enabling intricate designs that can be transferred to fabrics. By properly using the DTF Gangsheet Builder, you can efficiently create custom apparel with vibrant colors and detailed prints.

How do I create designs using a DTF Gangsheet Builder?

To create designs with a DTF Gangsheet Builder, start by using graphic design software like Adobe Illustrator or Photoshop. Develop your designs ensuring they are in CMYK color mode and at a resolution of 300 dpi. Once your designs are finalized, arrange them using the DTF Gangsheet Builder, ensuring proper spacing to avoid overlaps during printing.

What are the benefits of using the DTF GangsheetBuilder for fabric printing?

The DTF Gangsheet Builder offers numerous advantages for fabric printing, such as economical production by allowing multiple designs on one sheet, versatility to cater to different customer preferences, and improved detail in prints. This method significantly enhances your printing capabilities while reducing waste and saving on materials.

What steps should I follow when printing with the DTF Gangsheet Builder?

When printing with the DTF Gangsheet Builder, follow these steps: 1) Create your designs in graphic design software, 2) Assemble the designs on the gang sheet layout, 3) Load the layout into a DTF printer with the correct settings, 4) Print using appropriate DTF films, 5) Apply adhesive powder, and 6) Cure the adhesive before transferring the designs onto fabric.

What issues might arise when using the DTF Gangsheet Builder, and how can I resolve them?

Common issues when using the DTF Gangsheet Builder include blurry prints, adhesive not sticking, or color misalignment. To resolve these, ensure your designs are high resolution (300 dpi), verify printer settings for DTF printing, check adhesive application temperature and duration, and ensure you are working in the correct color space (CMYK).

Can I use a DTF Gangsheet Builder for all types of fabrics?

Yes, a DTF Gangsheet Builder can be used on various fabric types, including cotton, polyester, and blends. DTF printing is versatile and allows for the application of detailed designs across different materials, making it an excellent choice for creating custom apparel and enhancing your fabric printing capabilities.

| Key Points | Details |

|---|---|

| Introduction | Overview of DTF printing and the DTF Gangsheet Builder’s role in enhancing fabric designs. |

| What is DTF Printing? | A method for transferring designs onto fabrics using a film that allows vibrant colors and detail. |

| Advantages of DTF Gangsheet Printing | Economical production, versatility in designs, and improved detail and quality. |

| Step 1: Design Creation | Choose software, create art aligned with printing specs, and maintain high resolution. |

| Step 2: Layout Preparation | Use the Builder to arrange designs cohesively, considering spacing. |

| Step 3: Printing | Load the layout into a DTF printer and select specific DTF settings. |

| Step 4: Applying Adhesive Powder | Apply adhesive powder immediately after printing and remove excess. |

| Step 5: Curing the Adhesive | Cure the printed sheet using heat to adhere the adhesive to the ink. |

| Step 6: Transferring to Fabric | Prepare the heat press and apply pressure and temperature for the transfer. |

| Common Issues and Solutions | Addressing issues like blurry prints, adhesive sticking, and color misalignment. |

Summary

DTF Gangsheet Builder is an innovative solution for creating unique and vibrant fabric designs efficiently. This powerful tool streamlines the fabric printing process, enabling designers to maximize productivity while producing high-quality outputs. By following the step-by-step guide outlined, you can effectively leverage the benefits of DTF printing, from design creation to the transferring process. The combination of cost-effectiveness, versatility, and enhanced detail makes DTF Gangsheet Builder an indispensable resource for anyone looking to elevate their fabric printing projects. Embracing this technique will not only enhance your creative capabilities but also align your work with current industry trends, ensuring that your designs stand out in a competitive marketplace.