The benefits of DTF printing are becoming increasingly prevalent in the custom apparel market, offering businesses a competitive edge in their printing needs. This innovative method, known as Direct to Film printing, combines versatility and efficiency, making it a formidable choice when compared to traditional techniques such as Direct to Garment (DTG) and screen printing. By producing high-quality images with vibrant colors and intricate details, DTF stands out as a top contender among cost-effective printing methods. Its ability to cater to a variety of materials adds to its allure, making it ideal for both fashion and promotional merchandise. As we delve deeper into its advantages, it’s clear that DTF printing may just redefine your approach to custom designs, enabling quicker turnaround times and reducing operational costs.

When discussing contemporary printing techniques, it’s essential to consider the myriad of alternatives available, particularly in the world of custom textiles. One such method gaining momentum is Direct to Film (DTF) printing, an innovative approach that allows for intricate designs to be transferred onto a variety of surfaces, significantly widening the scope of applications. In contrast to more established methods, such as Direct to Garment (DTG) and traditional screen printing, DTF boasts distinct advantages that cater to both quality and affordability. Whether addressing the needs of small orders or the demands for vibrant graphics, this method emerges as a superior choice worth exploring. By embracing these advanced printing technologies, businesses can enhance their offerings and satisfy the ever-evolving consumer preferences.

Understanding the Basics of DTF Printing

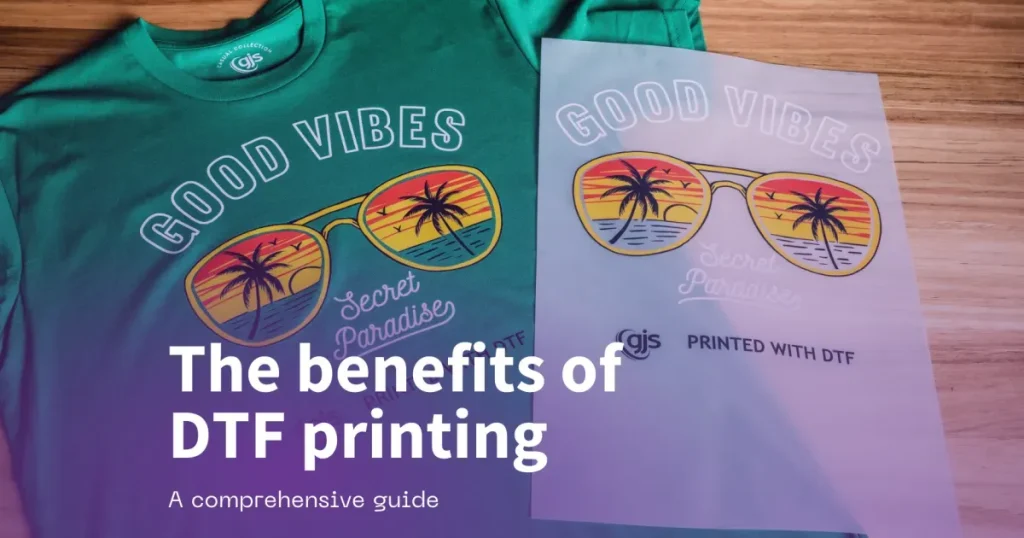

Direct to Film (DTF) printing is revolutionizing the way custom designs are brought to life. This innovative method involves printing a design onto a special film which can then be transferred to fabric using heat and pressure. The appeal of DTF printing lies in its ability to produce highly intricate designs and vibrant colors, making it a preferred choice for many businesses seeking diverse printing options. As the industry evolves, understanding how DTF works can help companies make informed decisions about their printing needs.

Compared to traditional printing methods such as Direct to Garment (DTG) and screen printing, DTF printing offers greater flexibility in terms of the materials that can be used. While DTG often favors cotton fabrics, DTF can successfully adhere to a wide range of textiles, including polyester and blends. This characteristic significantly broadens its applications to include not just clothing, but also accessories and promotional merchandise, thus catering to a larger market.

Benefits of DTF Printing

The benefits of DTF printing are manifold, particularly for businesses seeking a reliable and effective printing method. First and foremost, DTF printing provides an unmatched versatility that allows designs to be printed on various fabric types without sacrificing quality. This is a significant advantage when compared to screen printing, which is generally limited to specific materials. By utilizing DTF technology, designers can explore more creative avenues, knowing that their designs can be faithfully reproduced across different textiles.

Moreover, DTF printing is not just about versatility; it’s also about achieving high-quality results. The method can produce stunningly vibrant images and intricate designs that are comparable to what one might achieve with screen printing techniques. This commitment to quality ensures that businesses can deliver products that not only meet but exceed customer expectations, ultimately fostering brand loyalty and satisfaction.

DTF Printing vs DTG: A Comparative Analysis

When comparing DTF printing and Direct to Garment (DTG) printing, several key distinctions emerge. DTF printing tends to require a shorter setup time, making it ideal for smaller print runs or on-demand printing. In contrast, DTG printing often necessitates extensive preparation and is best suited for larger batches, where the time invested can be justified. This efficiency difference makes DTF a more attractive option for companies looking to quickly respond to fluctuating market demands.

Additionally, DTF’s ability to print on various materials gives it an edge over DTG, which is primarily effective on cotton. This characteristic allows businesses engaged in diverse sectors, such as fashion or promotional items, to leverage DTF printing for a broader range of products. Ultimately, while both methods have their strengths, DTF may often prove to be the more versatile and cost-effective solution for many businesses.

Cost-Effective Printing Methods: Why DTF Stands Out

Cost-effectiveness is a primary concern for many businesses involved in custom printing. DTF printing shines in this regard, particularly for smaller orders that might not justify the high setup costs associated with traditional screen printing. With DTF, there is no need for extensive preparation or large minimum order requirements, allowing companies to print exactly what they need when they need it. This on-demand capability not only reduces waste but also minimizes storage costs associated with unsold inventory.

Moreover, with its high-quality outputs and efficiency, DTF printing can also help to enhance overall profitability. The ability to quickly produce high-quality designs allows businesses to respond to trends and customer demands more rapidly. This capacity to pivot without incurring high costs translates into a substantial competitive advantage, particularly in industries where speed and quality are critical to success.

Screen Printing Comparison: DTF vs Traditional Techniques

Screen printing has long been a staple in the world of custom apparel, but as technology advances, DTF printing offers an impressive alternative. One of the most notable differences is the setup process; DTF requires significantly less time and fewer resources to get started. Unlike screen printing, which may require multiple screens for multi-colored designs, DTF can print full-color images directly onto a film with a singular pass. This not only saves time but also reduces labor costs, making it an appealing option for businesses.

Additionally, the quality of prints produced by DTF can compete with, and often surpass, traditional screen printing, especially for intricate designs. Screen printing tends to be best suited for simpler graphics due to its reliance on creating individual layers for colors. In contrast, DTF’s ability to deliver high-resolution images without the need for multiple setups allows businesses to explore more complex and creative design possibilities without incurring prohibitive costs.

High-Quality Printing Techniques: The Edge of DTF

High-quality printing techniques are essential for any business serious about its branding and product offerings. DTF printing excels in this area, boasting the ability to deliver stunning details and vibrant colors that can enhance any garment or product. Unlike other methods, DTF allows for the reproduction of intricate designs that retain clarity and impact even after multiple washes, ensuring customer satisfaction and loyalty.

Furthermore, DTF’s advanced technology utilizes special inks that result in enhanced color vibrancy and durability. This means that businesses can confidently offer products that not only look good upon delivery but also maintain their quality over time. For any company focused on quality assurance in apparel production, investing in DTF printing can significantly elevate their brand reputation and customer experience.

Frequently Asked Questions

What are the key benefits of DTF printing over DTG printing?

DTF printing offers several advantages over Direct to Garment (DTG) printing, primarily its versatility. Unlike DTG, which works best on cotton fabrics, DTF can be applied to a variety of materials, including polyester and blends. Additionally, DTF printing boasts high-resolution images with vibrant colors, making it ideal for intricate designs.

How does DTF printing compare to traditional screen printing in terms of quality?

In terms of quality, DTF printing can rival screen printing, especially when it comes to complex designs that require detailed printing. DTF produces high-resolution images with brilliant colors and intricate details, making it an excellent choice for custom graphics.

Is DTF printing a cost-effective printing method for small orders?

Yes, DTF printing is highly cost-effective for small orders. Unlike screen printing, which incurs high setup costs, DTF allows for on-demand printing, minimizing waste and reducing operational costs. This feature makes it ideal for businesses with low-volume printing needs.

What are the advantages of using DTF printing for promotional merchandise?

DTF printing offers numerous benefits for promotional merchandise, including its versatility across various fabric types and the ability to produce high-quality, vibrant designs quickly. This efficiency in production ensures businesses can meet consumer demands and trends without incurring high costs.

How does DTF printing enhance creativity in custom apparel design?

DTF printing enhances creativity in custom apparel design by providing the flexibility to print on various materials, which is not possible with methods like DTG. This allows designers to explore a broader range of textiles and applications, resulting in unique and innovative merchandise.

What makes DTF printing a faster method compared to screen printing?

DTF printing is faster than screen printing primarily due to its reduced setup time. DTF eliminates the need for screens and allows for quicker processing of designs, enabling businesses to enjoy faster turnaround times and respond swiftly to changing market demands.

| Aspect | DTF Printing | Compared Methods |

|---|---|---|

| Versatility | Can be used on various materials including polyester, blends, and cotton. | DTG is limited mainly to cotton fabrics. |

| Quality and Detail | Produces high-resolution images with vibrant colors and intricate details. | Compared to screen printing, DTF can achieve similar quality, especially for complex designs. |

| Efficiency | Faster than traditional methods, especially for small runs, with reduced setup time. | Screen printing requires extensive setup, leading to longer production times. |

| Cost-Effectiveness for Small Orders | Ideal for low-volume orders with minimized operational costs. | Screen printing is often too costly for small batches due to setup fees. |

Summary

The benefits of DTF printing are substantial, and this method stands out as a modern solution for custom apparel printing. This innovative printing technique offers unmatched versatility, allowing businesses to print on a diverse range of materials beyond just cotton. With its ability to produce stunningly high-quality images, DTF printing excels in showcasing intricate designs that demand vibrancy and detail. Furthermore, its efficiency translates to faster production times, crucial for businesses responding to quick market demands, while its cost-effectiveness for small orders provides a financially viable option for many. Thus, considering the significant advantages in versatility, quality, efficiency, and cost, DTF printing is a highly advantageous choice that is transforming the landscape of custom apparel printing.