DTF transfers, or Direct-to-Film transfers, have recently become a go-to method for crafters and small business owners looking to create vibrant and durable prints on a variety of fabrics. Whether you’re a total novice or seeking ways to refine your technique, mastering DTF transfers is within your reach with the right guidance and tools. This beginner-friendly approach simplifies the printing process, allowing for stunning designs that pop on textiles like cotton and polyester. In this article, we’ll dive into effective DTF printing tips and the essential steps of the DTF transfer process, ensuring you have the knowledge you need to succeed. Get ready to explore a comprehensive guide on how to use DTF transfers to elevate your custom design projects!

Direct-to-Film technology, often referred to as DTF printing, has emerged as a favorite among DIY enthusiasts and enterprise owners alike, thanks to its efficiency and high-quality results. This innovative printing approach utilizes a specialized transfer film to print vibrant designs that can seamlessly adhere to various fabrics. Beginners will find that DTF printing not only allows for artistic expression but also provides a versatile solution for garment decoration. With thorough understanding and practical execution, mastering DTF techniques will open up a world of creative possibilities. Explore the essentials of this unique transfer method, and discover how to achieve impressive results in your crafting endeavors.

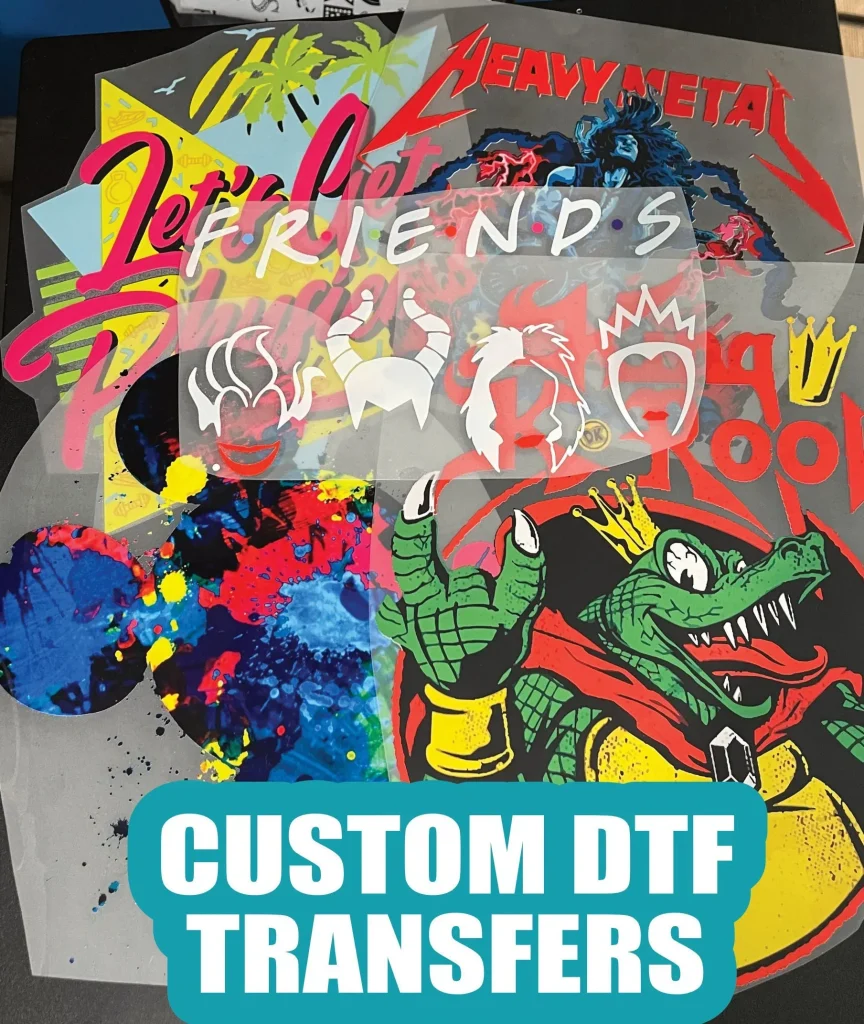

Understanding the Basics of DTF Transfers

Direct-to-Film (DTF) transfers represent a revolutionary method in the fabric printing landscape, creating an opportunity for both hobbyists and professionals to engage in high-quality printing. Unlike traditional methods, DTF transfers involve layering vibrant colors into a film that can easily be applied to various fabric types. This innovative technique not only enhances the color quality but also offers a level of flexibility and durability that can rival more established printing processes.

Moreover, the versatility of DTF printing cannot be overstated; it opens doors for printing on multiple materials including cotton, polyester, and even denim. It is this combination of vibrant output and adaptability that drives its growing popularity among new crafters. As we delve into the topic, understanding these foundational aspects of DTF transfer can empower beginners to experiment confidently with this exciting technology.

Essential Equipment for Successful DTF Printing

Investing in the right equipment for DTF printing is crucial for achieving outstanding results. To get started, a dedicated DTF printer is highly recommended, as it ensures that the ink application and transfer film are compatible. While some inkjet printers can be used with modifications, investing in models specifically designed for DTF use greatly enhances the quality of your output.

In addition to the printer, other critical tools include DTF powder and a reliable heat press machine. The powder serves as an adhesive, binding the ink to the fabric after it is printed on the transfer film. The effectiveness of your heat press also significantly impacts how well the design adheres to the material. Choosing quality equipment not only streamlines your DTF transfer process but also elevates the overall quality of your print outputs.

Step-by-Step Guide for Beginners in DTF Printing

The DTF transfer process may seem intricate, but breaking it down into manageable steps can simplify your journey. Begin by creating your design using software such as Photoshop or Illustrator. Ensure your design is in high resolution and mirrored, as this is essential for proper application onto fabric. This foundational step lays the groundwork for a successful transfer.

Following the design phase, it’s crucial to print your creation onto the DTF film using the designated printer and DTF ink. Once the design is printed, the next step involves carefully applying the adhesive powder onto the wet ink, followed by curing the powder with a heat press. This combination of technique and timing is vital, as it prepares your design for a flawless transfer to fabric.

Best Practices for Using DTF Transfers

To maximize the potential of DTF transfers, beginners should adhere to best practices that enhance the quality of their prints. Experimenting with different fabric types is key to discovering what works best with your specific printer and adhesive settings. Each material can react differently, making it essential to test and adjust your approach accordingly to achieve the best results.

In addition to fabric experimentation, using high-quality inks and powders is non-negotiable for longevity and clarity in your prints. Investing in dependable materials can drastically reduce issues such as fading or peeling over time. By prioritizing quality and consistency in your DTF transfers, you will create designs that not only impress but also stand the test of time.

Common Challenges When Starting with DTF Transfers

As with any new technique, beginners venturing into DTF printing may encounter a few challenges along the way. Issues such as ink bleeding can arise if the printing process is not executed correctly or if the heat settings are inappropriate. Recognizing the warning signs of such problems early can help mitigate frustrations and lead to successful outcomes.

Another common hurdle is ensuring proper adhesion during the transfer process. If the adhesive powder is not applied evenly or sufficiently cured, the design may fail to bond correctly to the fabric, resulting in unwanted peeling after laundering. Gaining familiarity with these challenges and developing troubleshooting skills will significantly enhance your DTF printing experience.

Tips for Mastering DTF Transfers Efficiently

To truly master DTF transfers, continuous learning and adaptation are essential. Tapping into online resources such as YouTube tutorials can vastly expand your knowledge base and give you visual insights into complex processes. By observing experienced crafters, beginners can gather tips and techniques that will facilitate their own DTF printing journey.

Engagement in online forums and communities, like those on Reddit, allows beginners to interact with seasoned professionals and other users who share their experiences and solutions to common problems. Such interactions not only foster learning but also cultivate a support network that encourages your growth in mastering the art of DTF transfer printing.

Frequently Asked Questions

What is the DTF transfer process and how does it work?

The DTF transfer process involves printing a design onto a special film using a DTF printer, applying adhesive powder to the wet ink, curing the powder with heat, and then pressing the film onto fabric. This method allows vibrant colors and durable prints on various materials.

How do I use DTF transfers effectively as a beginner?

To use DTF transfers effectively, start by creating a high-resolution design in graphic software, print it on DTF transfer film, apply adhesive powder while the ink is wet, cure the powder with a heat press, and then transfer the design onto your fabric.

What are some essential DTF printing tips for beginners?

Here are some essential DTF printing tips: invest in quality DTF printers and materials, experiment with different fabrics, mirror your design before printing, ensure proper heat settings during the transfer, and learn from online tutorials and communities.

Can DTF transfers be used on all types of fabric?

Yes, DTF transfers are versatile and can be used on various types of fabrics, including cotton, polyester, denim, and blends. However, testing on different materials is advised to determine the best settings for each type.

What challenges can beginners face when mastering DTF transfers?

Common challenges include ink bleeding due to poor printing settings, adhesion issues if the powder isn’t applied correctly, and maintenance problems with the printer. It’s important to troubleshoot these issues as you learn.

Where can I find resources to improve my DTF printing skills?

You can find resources to improve your DTF printing skills on platforms like YouTube for tutorials, online forums for discussions, and printing blogs that offer guides and tips tailored to beginners.

| Key Point | Details |

|---|---|

| What are DTF Transfers? | DTF transfers involve printing designs onto a special film which are then transferred to fabric using heat, resulting in vibrant prints that can withstand washing and wear. |

| Benefits of DTF Transfers | Vibrant colors, versatility on various materials, and durability comparable to screen printing. |

| Essential Equipment | 1. DTF Printer, 2. DTF Powder, 3. Heat Press Machine, 4. DTF Transfer Film. |

| Step-by-Step Process | 1. Create your design. 2. Print the design. 3. Apply adhesive powder. 4. Cure the powder using heat. 5. Transfer the design onto the fabric. |

| Tips for Beginners | Experiment with materials, use high-quality supplies, and learn from online resources like tutorials and forums. |

| Common Challenges | Ink bleeding, adhesion issues, and maintenance of equipment. |

| Resources for Learning | YouTube tutorials, online forums, and printing blogs providing insights and tips. |

Summary

DTF transfers are rapidly becoming a favorite choice for crafters and small businesses looking to produce high-quality and colorful fabric prints. This innovative printing method allows individuals to print designs onto transfer film and apply them onto various types of fabrics with impressive fidelity. By mastering the basics of DTF transfers—including understanding the equipment, following effective procedures, and overcoming common challenges—beginners can transform their creative ideas into reality. With ongoing practice and learning from available resources, soon you’ll be making beautiful prints efficiently and with confidence.