In the evolving landscape of custom apparel printing, DTF transfers have emerged as a game-changer, offering a seamless solution for entrepreneurs and designers alike. DTF transfers, or Direct-to-Film transfers, enable the creation of vibrant and detailed designs on a variety of fabrics, making them an ideal choice for small business owners looking to expand their offerings. Unlike traditional printing methods, DTF transfer technology provides exceptional print quality and durability, ensuring that your custom creations withstand the test of time. With lower setup costs and a straightforward production process, this technique has opened doors for creativity and innovation in the custom apparel market. Whether you’re looking to print on t-shirts, hoodies, or accessories, understanding DTF transfers can elevate your product line to new heights.

Exploring the world of Direct-to-Film printing reveals numerous possibilities for those in the custom garment sector. This innovative transfer method allows for high-resolution images and intricate designs that are easily adaptable to different fabric types, ensuring versatility in your creations. As the demand for personalized merchandise continues to rise, techniques such as DTF transfer technology stand out as efficient and effective solutions for entrepreneurs. Additionally, the durability of prints produced via DTF is unmatched, providing long-lasting designs that maintain their vibrancy through countless washes. Embracing this modern approach to custom apparel printing not only enhances product appeal but also caters to diverse customer preferences.

Understanding the DTF Printing Process

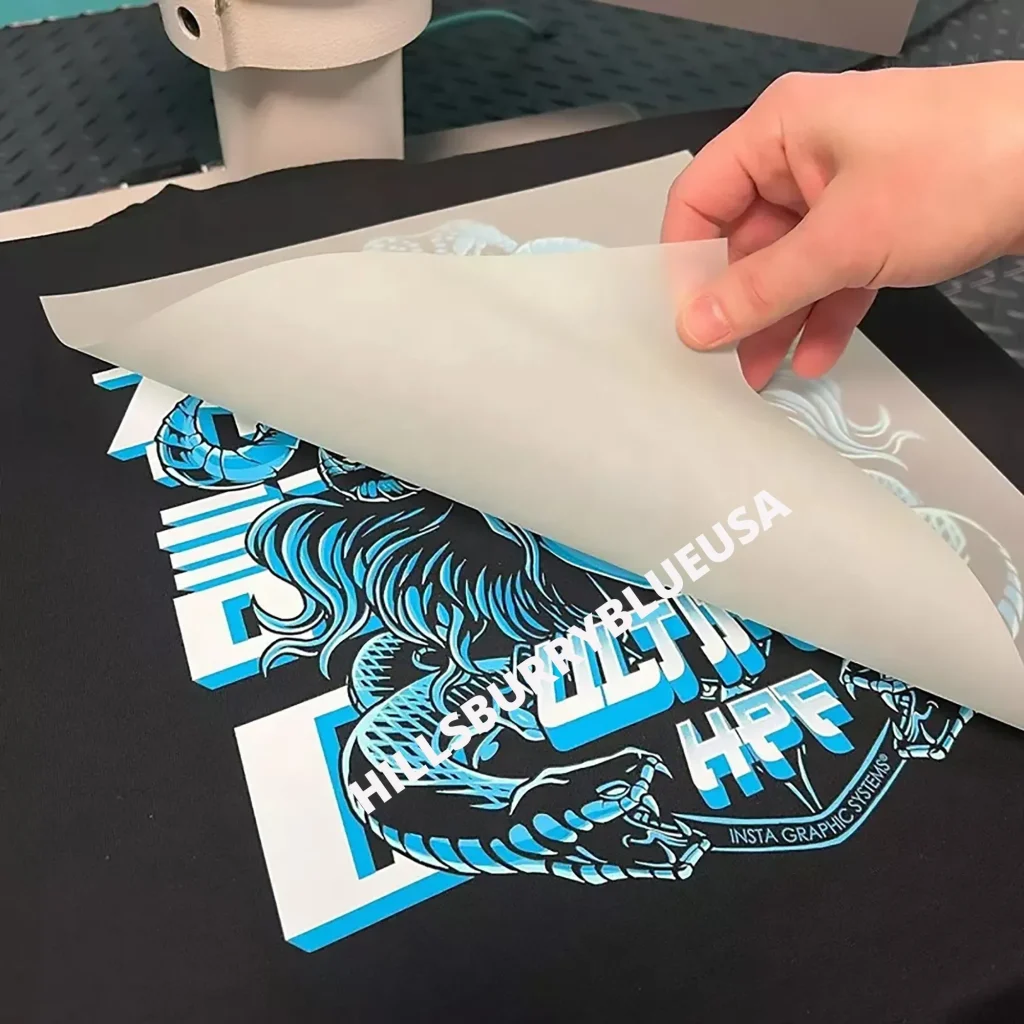

The Direct-to-Film (DTF) printing process begins with the creation of a digital design, which is then printed onto a specialized film. Unlike traditional printing, DTF transfers utilize a unique adhesive along with high-quality inks, which ensure that colors remain vibrant and the details are exceptionally crisp. The film acts as a medium where the design is intricately captured, making it ideal for complex graphics that require precision. The entire process not only emphasizes print quality but also accommodates the diverse fabric types commonly used in apparel.

Once the design is printed, the transfer process is initiated, where heat and pressure are applied to bind the ink to the fabric. This step is critical, as the quality of the heat press can significantly impact the durability of the final product. A well-executed transfer can result in an image that won’t crack or peel, providing a long-lasting finish that enhances the garment’s appeal. The careful attention to both the printing and transfer phases is what sets DTF printing apart from other custom apparel techniques.

Benefits of Using DTF Transfers for Custom Apparel

One of the standout benefits of utilizing DTF transfers is the print quality achieved. This method produces stunning visuals with vibrant colors and fine details that can rival traditional methods like screen printing or direct-to-garment printing. The ability to print on various fabrics without compromising quality makes DTF a versatile solution for any custom apparel business aiming to cater to a broad audience. Additionally, DTF prints have remarkable durability, ensuring that your designs remain intact even after multiple washes.

From a business perspective, DTF transfers are extremely cost-effective. Entrepreneurs can enjoy lower start-up costs due to the affordability of the necessary equipment compared to large-scale printing setups. Moreover, the quick turnaround times offered by DTF printing can help small businesses meet customer demands efficiently, enhancing overall productivity. The combination of high-quality output and cost efficiency makes DTF transfers a compelling choice for anyone entering the custom apparel market.

Exploring DTF Transfer Technology Advancements

As the popularity of DTF printing surges, leading manufacturers are continuously innovating to improve the technology. Companies like Brother Industries are at the forefront, creating DTF printers that enhance the capabilities of small businesses. These advancements include better print resolution, faster printing speeds, and improved ink formulations. Innovations in DTF technologies not only broaden the scope of what can be printed but also increase overall operational efficiency.

The latest DTF printers have been designed with user-friendly features that cater to a variety of skill levels, making it accessible for beginners and seasoned printers alike. Many of these machines come equipped with preloaded profiles for different fabric types, simplifying the setup process and ensuring consistent results. By investing in the latest DTF technology, businesses can maximize their production potential while maintaining high standards of quality.

Choosing the Right Equipment for DTF Printing Success

Selecting the appropriate equipment is crucial for achieving success in DTF printing. A quality DTF printer is essential, as it directly affects the print quality and efficiency. Top-rated models like the Procolored Printer P13 have earned favorable reviews for their ability to produce vibrant images rapidly, making them ideal for small businesses aiming to fulfill customer orders effectively. Entrepreneurs should prioritize printers that are specifically designed for DTF use, as these models incorporate features that enhance print durability.

In addition to the printer, investing in a high-quality heat press is critical for the DTF transfer process. A heat press that maintains consistent temperature and pressure will result in better adhesion of the design to the fabric. Business owners should also consider the quality of DTF films and adhesives they are purchasing, as superior materials contribute to the overall success and longevity of their printed apparel. The right equipment selection can make a significant difference in production outcomes and customer satisfaction.

Steps to Launch Your DTF Printing Business

Launching a DTF printing business involves several strategic steps. Initially, conducting thorough market research is vital to understand the competition and identify your target audience. Knowing the trends in custom apparel printing will help you tailor your designs and services to appeal to potential customers. This phase encourages entrepreneurs to carve a unique niche, defining what sets their offerings apart in the crowded marketplace.

Following your research, it is essential to create a comprehensive business plan that outlines your goals, budget, and marketing strategies. Consider how you will position your DTF printed products in the market and establish competitive pricing. Once the groundwork is laid, focus on procuring the necessary equipment, experimenting with designs, and building an online presence through social media channels, which can dramatically enhance visibility for your brand.

Frequently Asked Questions

What are DTF Transfers and how do they work?

DTF transfers, or Direct-to-Film transfers, involve a process where designs are printed onto a special film and then transferred to fabrics using heat and pressure. This method allows for high-quality prints with vibrant colors, making it popular for custom apparel printing.

What is the print quality like with DTF printing?

DTF printing is known for its stunning print quality that rivals traditional methods like screen printing and direct-to-garment printing. It offers vibrant colors and intricate details, ensuring that custom designs stand out on apparel.

Are DTF transfers a cost-effective option for small businesses?

Yes, DTF transfers present a cost-effective solution for small business owners. The materials and equipment for DTF printing often have lower entry costs compared to other printing methods, and the efficient production process leads to quicker turnaround times.

What materials can DTF transfers be applied to?

DTF transfers are versatile and can be applied to a variety of fabric types, including cotton, polyester, and blends. This versatility allows entrepreneurs to create a wider range of products, from t-shirts to bags, all using the same printing process.

How durable are DTF printed designs?

DTF printed designs are known for their durability and resistance to fading, peeling, and cracking, even after multiple washes. This ensures that custom apparel maintains its quality over time, satisfying customers and encouraging repeat business.

What equipment do I need to start using DTF transfer technology?

To start with DTF transfer technology, you’ll need a reliable DTF printer, a quality heat press, and high-grade DTF films and adhesives. Investing in dependable equipment ensures that you can achieve the best print quality while meeting customer demands.

| Key Points | Details |

|---|---|

| What are DTF Transfers? | Printed designs on film transferred to fabrics using heat and pressure. |

| Advantages of DTF Transfers | 1. High-quality prints. 2. Cost-effective solutions. 3. Versatile for various fabrics. 4. Durable and wash-resistant. |

| Technology Behind DTF Printing | Involves advanced printers and a three-step process: printing to film, transferring using heat, and finishing by peeling film. |

| Choosing the Right Equipment | Invest in reliable printers, quality films and adhesives, and a decent heat press. |

| Steps to Start DTF Printing | 1. Research market. 2. Purchase equipment. 3. Experiment with designs. 4. Create a business plan. 5. Promote products. |

Summary

DTF Transfers are essential for those interested in entering the custom apparel market. This innovative printing method combines high-quality outputs with cost-effective solutions tailored for small business owners and entrepreneurs. As the demand for custom products continues to expand, understanding DTF transfers becomes increasingly important. By selecting the right equipment and mastering the DTF process, you can seize the opportunity to create outstanding products that not only meet customer expectations but also thrive in a competitive landscape. Whether you’re just starting or looking to enhance your existing business, DTF transfers offer you the tools needed to succeed and establish a unique brand presence in the custom printing arena.