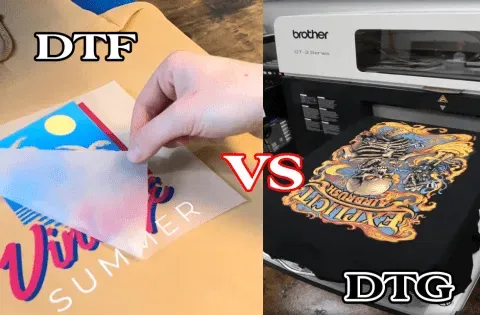

When deciding between DTF vs DTG for your custom apparel printing projects, understanding the key differences between these two printing methods is essential. DTF (Direct to Film) and DTG (Direct to Garment) each offer unique advantages that cater to different needs in textile printing techniques. For instance, DTG printing is renowned for its high-quality detail and vibrant colors, while DTF printing boasts flexibility across various fabrics, making it attractive for diverse custom projects. In this comparative guide, we will delve into the nuances of these popular printing techniques, helping you discern which method aligns best with your creative and practical requirements. Exploring DTF printing versus DTG will empower you to make informed decisions for your custom apparel, whether for personal use or business.

In the realm of personalized garment decoration, two standout techniques emerge: Direct to Film (DTF) and Direct to Garment (DTG) printing. These methods, pivotal in the industry, showcase distinct approaches to bringing designs to life on fabric. DTF printing leverages film transfers to apply images onto various textile materials, while DTG printing directly applies ink onto the garment itself. Understanding how these printing approaches differ not only aids in selecting the right method for your projects but also enhances your knowledge of current textile printing trends. By comparing DTF and DTG, you’ll uncover which solution best meets the demands of your apparel printing needs.

DTG Printing Explained: An In-Depth Look

Direct to Garment (DTG) printing is a revolutionary method that allows for high-quality, detailed designs to be printed directly onto textiles. This technique is particularly popular for creating custom apparel due to its ability to produce vibrant colors and intricate patterns without a significant setup process. DTG printing is performed using specialized inkjet technology that injects water-based inks directly onto the fabric surface, typically cotton or cotton-blend materials. This allows for impressive detail and color blends, making it a preferred choice for clothing designs that require a photo-realistic quality.

DTG printing offers significant benefits for small to medium production runs, as it eliminates the need for setup costs that are often associated with traditional screen printing methods. It is an eco-friendly option as it primarily utilizes water-based inks that are less harmful to the environment. However, the method does have its limitations; DTG prints are best suited for natural fibers, particularly cotton, and can struggle with synthetic materials. Additionally, while the vibrancy of the prints is exceptional, the speed of production can be slower when handling larger orders, often making it less suitable for mass production scenarios.

Frequently Asked Questions

What are the main differences between DTF vs DTG printing methods?

The main differences between DTF (Direct to Film) and DTG (Direct to Garment) printing include the types of fabrics they best work with, production speed, and print durability. DTF is versatile and can print on a wide range of materials, making it ideal for mixed textiles, while DTG excels on 100% cotton fabrics and offers superior detail and color vibrancy. Additionally, DTF allows for faster production for larger orders, whereas DTG is better suited for small custom batches.

Which printing method is better for custom apparel—DTF vs DTG?

The choice between DTF and DTG for custom apparel depends on your specific needs. If you require vibrant colors and intricate designs primarily on cotton, DTG is the better choice. However, if you need to print on various fabric types, including synthetic materials, and prioritize durability and production speed, DTF printing is preferable.

Is DTF printing more cost-effective than DTG printing?

In terms of initial investment, DTF printing generally has a lower entry cost compared to DTG. However, ongoing supply costs like film and transfer materials can add up. For small custom runs, DTG avoids setup costs, making it more cost-effective in certain scenarios. Ultimately, the cost-effectiveness of either method depends on your specific production needs and order sizes.

How do the durability levels compare in DTF vs DTG printing?

DTF printing typically offers superior durability compared to DTG printing. DTF prints resist fading and cracking better, making them suitable for clothing that undergoes frequent washing. Conversely, while DTG prints provide good durability, they may fade over time, particularly if washed improperly.

What materials can be used for DTF vs DTG printing?

DTG printing is optimized for 100% cotton and cotton-blended materials, which limits versatility for other textile types. In contrast, DTF printing is versatile and can be used on a wide array of fabrics, including cotton, polyester, and blends, making it ideal for various applications from sportswear to work uniforms.

What are the production speeds for DTF vs DTG printing?

Production speed is a notable difference between DTF and DTG printing methods. DTF allows for faster production, especially for larger batches, as multiple designs can be printed on films simultaneously. In contrast, DTG printing is slower because it prints each garment individually, which can hinder efficiency for larger orders.

| Feature | DTG | DTF |

|---|---|---|

| Best Fabric | 100% cotton, cotton-blends | Wide range, including synthetic |

| Production Speed | Slower for large orders | Faster for large batches |

| Durability | Good, but can fade | Excellent, more resistant |

| Setup Requirement | Individual garments | Multiple designs at once |

| Investment Cost | Higher initial cost | Generally lower initial cost |

Summary

DTF vs DTG are two leading printing methods in the custom apparel industry, each catering to different needs and preferences. DTG printing is ideal for intricate designs and vibrant colors on cotton fabrics, making it perfect for personalized and small-batch items. However, it can be slower and has durability concerns over time. DTF, by contrast, shines in its versatility, being able to print on a broad range of fabrics including polyester, and offers faster production speeds and greater durability. Understanding the differences between these two methods ensures you choose the right technique for your specific project requirements, maximizing the quality and efficiency of your apparel printing.