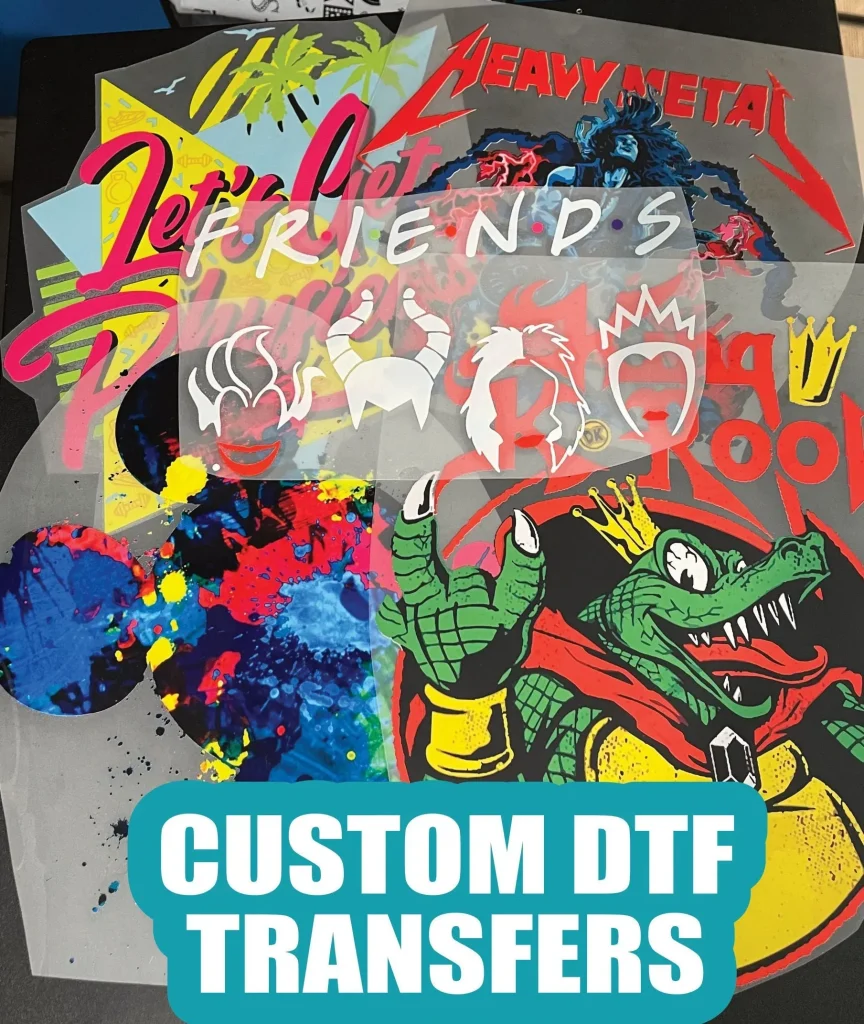

DTF transfers, or direct to film transfers, have revolutionized the world of fabric decoration, enabling businesses and enthusiasts alike to create stunning custom apparel. This innovative technology utilizes high-quality printing techniques to transfer vibrant designs onto a variety of fabrics, making it a preferred choice for garment printing. As consumers increasingly seek personalized clothing options, understanding the benefits and application process of DTF transfers is essential for anyone involved in the custom apparel market. From its cost-effectiveness to its durability, DTF printing addresses the needs of modern consumers who value both style and quality. Dive into the world of DTF transfers to discover how they are transforming apparel printing and enabling creative expression in endless ways.

Also known as direct-to-film printing, DTF transfers represent a significant advancement in the realm of garment embellishment. This technique is gaining popularity for its ability to apply intricate graphics to various fabric types, catering to the growing demand for bespoke clothing solutions. As more individuals and brands explore heat transfer methods for fabric decoration, understanding the nuances of DTF technology becomes increasingly important. With its remarkable versatility, this printing process not only enhances visual appeal but also boosts the durability of designs on custom apparel. Engaging with DTF transfers allows creators to push the boundaries of fabric printing and artistic expression.

What Are DTF Transfers and How Do They Work?

Direct to Film (DTF) transfers revolutionize the way we approach fabric decoration by allowing artists and designers to print stunning graphics directly onto a specialized film. This film is then heat-pressed onto the chosen fabric, resulting in vivid prints that boast excellent durability and color accuracy. Unlike traditional methods such as screen printing, DTF transfers can handle intricate designs with high levels of detail, making them particularly appealing for custom apparel businesses looking to showcase unique styles.

The technology behind DTF printing enables a seamless transfer process that accommodates various fabrics, including cotton, polyester, and blends. Once the printing is done, an adhesive powder is applied, which enhances the bond between the design and the fabric during the heat transfer process. This versatility ensures that DTF transfers are not only effective for producing detailed images, but also suitable for a wide range of applications, from fashion pieces to promotional merchandise.

Advantages of Using DTF Transfers in Custom Apparel

One of the primary advantages of utilizing DTF transfers for custom apparel is the level of detail they can achieve. With the ability to print high-resolution images, businesses can offer customers vivid designs that remain sharp and appealing even after multiple washes. This quality reduces the need for frequent reprints, ultimately saving time and resources for small business owners.

Additionally, DTF transfers are incredibly cost-effective. The process requires minimal setup compared to traditional screen printing methods and is ideal for on-demand printing. This means that businesses can respond quickly to customer requests without overcommitting to inventory, allowing for a more dynamic and flexible approach to custom apparel.

Exploring the Types of Fabrics Compatible with DTF Transfers

DTF transfers are highly versatile and can be applied to a range of fabric types with impressive results. Cotton is one of the most popular options, known for its ability to absorb color effectively and provide a vibrant finish. Users often commend the wash durability of DTF transfers on cotton garments, which maintain their appearance through numerous washing cycles, making them a reliable choice for everyday wear.

Polyester fabrics also work excellently with DTF technology. Not only do they offer a smooth surface for the transfers, but they also benefit from the heat transfer’s strong adherence. This feature makes polyester ideal for activewear and sports uniforms, where durability and performance are essential. Blended fabrics, too, prove to be a practical choice for DTF transfers, allowing custom designers to diversify their apparel offerings without compromising quality.

Current Trends and Innovations in the DTF Transfer Market

The DTF transfer market is experiencing rapid innovations that are shaping the future of apparel printing. Companies like Sam’s DTF Transfers are at the forefront, emphasizing high-quality, customizable options that cater to growing consumer demand for unique clothing items. As e-commerce continues to rise, businesses are increasingly looking for printing solutions that allow for personalization without the need for large-scale operations.

Furthermore, advancements from companies such as Insta Graphic Systems highlight the emphasis on performance and versatility in fabric decoration. The introduction of enhanced DTF products brings forth significant improvements in transfer quality, allowing businesses to expand their fabric selections and improve the overall customer experience. As the technology evolves, staying informed about these innovations will be critical for those in the custom apparel industry.

Best Practices for Applying DTF Transfers Effectively

To maximize the potential of DTF transfers, adhering to best practices during the application process is essential. Preparation of the fabric is paramount; ensuring that it is clean and devoid of any dust or residues can significantly affect the adhesion of the transfer. Pre-washing fabrics to remove sizing or treatments can further enhance the bond, leading to a more successful application.

During the actual application, it’s critical to follow the specific temperature and pressing time guidelines for each fabric type. Using a quality heat press will ensure even heat distribution, which is vital for the transfer’s durability. After pressing, allowing the transfer to cool before removing the film helps secure the design, ensuring it adheres properly and maintains its integrity through wear and washing.

Understanding the Future of DTF Printing Technology

As the custom apparel industry grows, so does the potential for DTF printing technology. With continuous advancements in ink formulations and printing techniques, the quality of DTF transfers will only improve. Innovations aimed at increasing speed, reducing costs, and enhancing user-friendliness are likely to become standard, enabling more businesses to adopt this method for their custom garment needs.

Looking forward, integrating DTF technology with e-commerce platforms may offer new opportunities for personalization and consumer engagement. As more businesses embrace online sales, the capacity for on-demand printing and swift delivery will become essential differentiators in a crowded market. Understanding these evolving trends will help businesses leverage DTF transfers strategically to stay competitive.

Frequently Asked Questions

What are DTF transfers and how do they differ from other printing methods?

DTF transfers, or Direct to Film transfers, involve printing designs onto a special film that can be transferred onto various fabrics using heat. Unlike traditional printing methods, such as screen printing, DTF allows for vibrant colors and intricate details to be applied on-demand, making it ideal for custom apparel.

How do I apply DTF transfers on different fabrics effectively?

To apply DTF transfers effectively, start by preparing your fabric thoroughly. Use a heat press to apply the transfer following the correct temperature and time specifications for your fabric type. Proper preparation, including cleaning and pre-washing fabrics, and adherence to application guidelines, ensures lasting results.

What types of fabrics work best with DTF transfers?

DTF transfers work exceptionally well on 100% cotton, polyester, and cotton/polyester blends. They provide vibrant colors and durability across these fabric types, making them suitable for a range of custom apparel applications, including sports uniforms and fashion wear.

What are the benefits of using DTF printing for custom apparel?

The benefits of DTF printing for custom apparel include high-resolution prints with intricate details, excellent wash durability, and cost-effectiveness. DTF transfers are particularly beneficial for small businesses, as they allow for on-demand printing with minimal setup.

How has the DTF transfer market evolved recently?

The DTF transfer market has seen significant advancements, with companies like Sam’s DTF Transfers and Insta Graphic Systems enhancing product quality and versatility. These innovations focus on improving the application process and overall efficiency, making DTF a popular solution in fabric decoration.

Can DTF transfers fade or peel after washing?

No, one of the key advantages of DTF transfers is their durability. They typically withstand multiple wash cycles without fading or peeling, provided the application process was followed correctly. Regularly using the appropriate washing methods further extends the life of DTF printed garments.

| Key Point | Description |

|---|---|

| Understanding DTF Transfers | DTF transfers involve printing designs onto film that transfer onto fabrics, allowing for vibrant and intricate designs. |

| Recent Developments | Companies like Sam’s DTF Transfers and Insta Graphic Systems are enhancing DTF technology and services for custom apparel. |

| Application Process | Key steps include preparation, printing, applying adhesive, heat pressing, and peeling. |

| Fabric Versatility | DTF transfers can be applied successfully on cotton, polyester, and cotton/polyester blends. |

| Benefits of DTF Transfers | DTF transfers offer high-resolution prints, durability, and cost-effectiveness. |

Summary

DTF transfers are revolutionizing the custom apparel industry due to their versatility and adaptability to different fabrics. This innovative process allows for high-quality, vibrant designs that ensure durability and detail. As the industry experiences growth with new advancements from leading companies, understanding the application techniques and benefits of DTF transfers becomes essential for creators and businesses alike. Embracing DTF technology not only enhances the quality of custom garments but also opens up new possibilities in the world of textile decoration.