Introducing the DTF Gangsheet Builder, an essential tool for anyone looking to excel in the custom garment printing industry. This innovative solution utilizes the Direct-to-Film (DTF) printing method, allowing users to create vibrant garment prints that are both intricate and durable. With its user-friendly interface and efficient setup, the DTF Gangsheet Builder simplifies the gangsheet printing process, enabling designers to maximize their creativity without compromising quality. As demand for personalized apparel rises, savvy entrepreneurs are turning to the DTF print process for its cost-effectiveness and versatility across various fabrics. Dive into this guide to explore how the DTF Gangsheet Builder can revolutionize your approach to custom designs and set your work apart in a competitive market.

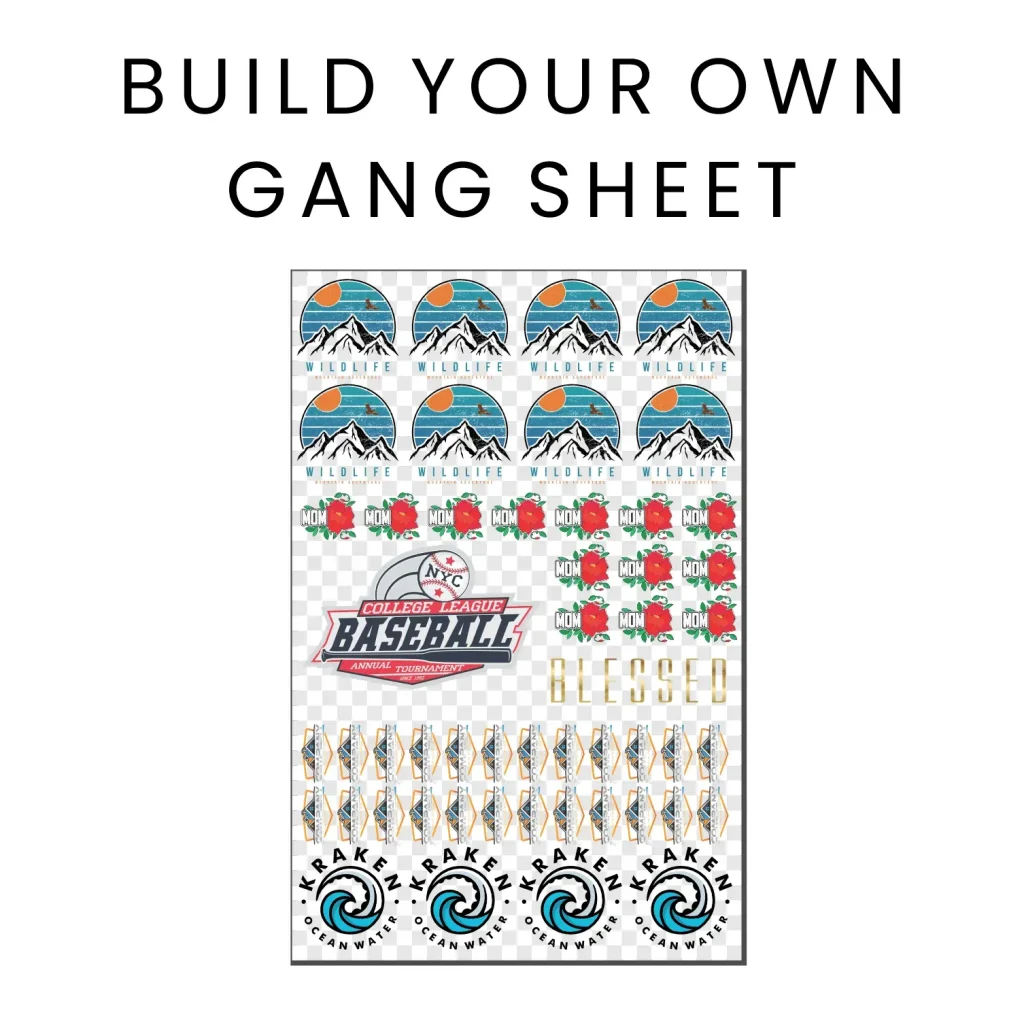

The DTF Gangsheet Builder is a powerful resource for artists and entrepreneurs interested in advanced garment decoration techniques. Often referred to as Direct-to-Film printing, this method combines innovative technology with a streamlined approach to printing vibrant designs onto diverse materials. The gangsheet printing strategy effectively organizes multiple designs on a single sheet, significantly reducing waste and enhancing efficiency in the custom garment printing landscape. With the ability to produce high-quality results that withstand the test of time, this technique is ideal for those aspiring to deliver stunning, durable prints that resonate with clients and customers alike. Explore the world of custom prints with the DTF Gangsheet Builder and unleash your creative potential.

Understanding the DTF Print Process

Direct-to-Film (DTF) printing is a revolutionary method that allows for the transfer of brilliant designs onto fabrics through a unique film process. This technique starts with printing your design onto a special PET film, which is then coated with adhesive powder before being cured. The beauty of DTF is in its layering system, where multiple prints can be arranged efficiently on a gangsheet, maximizing resource usage while ensuring that each garment receives vibrant and durable prints.

One of the biggest advantages of the DTF print process is its versatility. The technology enables printing on various fabric types, including cotton, polyester, and different blends, making it an excellent choice for custom garment printing. DTF is particularly favorable for intricate designs, as it supports detailed artwork without compromising on color vibrancy or quality. Moreover, as designs transfer effectively onto fabrics, they maintain their vividness, even after several washes.

The Benefits of Using the DTF Gangsheet Builder

Employing the DTF Gangsheet Builder allows for streamlined production processes, saving both time and resources. When multiple designs are printed on a single gangsheet, it minimizes waste and optimizes ink use, making it an economically efficient solution for printers. This method is especially advantageous in custom garment printing as it caters to smaller batches and diverse orders without the need for extensive setup, enabling quicker turnaround times for your customers.

Additionally, the DTF Gangsheet Builder enhances creativity by permitting printers to mix and match designs on a single sheet. This flexibility encourages experimentation with different styles and concepts while also maintaining consistency in quality. Each print offers vivid, eye-catching results that contribute to a professional end product, essential for attracting customers in today’s competitive printing market.

Tips for Successful DTF Printing

To achieve remarkable results with DTF printing, maintaining a high quality of your designs is crucial. Always start with high-resolution images, ensuring they are at least 300 DPI to preserve sharpness and detail. Furthermore, when setting up your gangsheet template, arrangement is key. Adequately spacing your designs helps to prevent overlapping during the printing and cutting processes. This attention to detail will significantly reduce errors and enhance the overall quality of your prints.

In addition to preparation, conducting test prints using different settings is advisable. Since fabric types can vary widely, do not hesitate to adjust heat and pressure settings to find the optimal combination for each material. Regularly testing your prints allows for rapid troubleshooting of any potential color clarity or alignment issues and contributes to refining your technique to achieve the best possible results.

Maximizing Vibrancy in Your Prints

Creating vibrant garment prints is all about understanding the materials and processes involved. With DTF printing, achieving rich colors starts with selecting the right inks and using the correct temperature settings during the printing process. Ensuring your DTF printer is correctly calibrated will directly affect the vibrancy of the final output. This consideration is paramount, as vibrant and striking prints are essential in drawing attention to your custom designs.

Furthermore, the adhesive plays a significant role in ensuring that colors remain vibrant after multiple washes. Properly curing the adhesive powder is critical; if it is under-cured, the print may fade or peel over time. Taking the time to correctly apply adhesive and perform a final heat press not only secures the design but also enhances the longevity of vibrant prints, ensuring that customers are satisfied with their orders.

Exploring Future Trends in DTF Printing

As DTF printing evolves, so do its applications and technology. Innovations in ink formulations, film materials, and printing equipment are continuously emerging, promising to further enhance the quality and efficiency of DTF printing. Staying updated on these trends is essential for any printer looking to remain competitive and provide the best possible options to their customers.

The rise of eco-friendly materials in custom garment printing is also an important movement to watch. Manufacturers are developing more sustainable inks and films that minimize environmental impact while still delivering dazzling prints. By adopting these new materials, printers can appeal to the growing market of environmentally-conscious consumers, setting their businesses apart through both quality and ethical practices.

Resources for Learning and Improvement in DTF Printing

For individuals or businesses looking to deepen their understanding of DTF printing, various resources are available. Online platforms such as YouTube offer a plethora of tutorial videos that demonstrate the DTF printing process in an easy-to-follow format. These visual guides can be very beneficial for both beginners and seasoned printers alike, helping to refine techniques and introduce new strategies.

Additionally, joining online forums and communities dedicated to DTF printing can provide valuable insights and peer support. Engaging with fellow printers allows you to share experiences, troubleshoot challenges, and discover innovative practices emerging in the industry. Investing time in these communities not only enhances your printing skills but also fosters connections that can lead to collaboration and shared success.

Frequently Asked Questions

What is the DTF Gangsheet Builder and how does it work?

The DTF Gangsheet Builder is a tool used in the Direct-to-Film (DTF) printing process to create multiple design prints on a single sheet. This method allows users to efficiently produce vibrant garment prints by arranging their artwork on a gangsheet, minimizing material waste and optimizing production time.

How does DTF printing differ from traditional printing methods?

DTF printing differs from traditional printing methods by using a specialized film to transfer designs onto garments. This process produces vibrant, detailed prints that can adhere to a wide variety of fabrics and withstand multiple washes, providing advantages over processes like screen printing or heat transfer.

What advantages does DTF gangsheet printing offer for custom garment printing?

DTF gangsheet printing offers several advantages for custom garment printing, including cost efficiency by allowing multiple designs on one sheet, versatility across different fabric types, and high quality prints that maintain their vibrancy and detail even after numerous washes.

What are the important steps in the DTF print process using the Gangsheet Builder?

The DTF print process using the Gangsheet Builder includes preparing designs in high resolution, printing them onto specialized film, applying adhesive powder, and then transferring the designs onto garments using a heat press. Each step is crucial for achieving stunning, vibrant garment prints.

Can the DTF Gangsheet Builder be used for large batch orders?

Yes, the DTF Gangsheet Builder is ideal for large batch orders as it allows users to print multiple designs on a single sheet, maximizing ink usage and reducing overall production time. This efficiency is particularly beneficial for custom garment printing on a larger scale.

What tips can improve my results when using the DTF Gangsheet Builder?

To improve results when using the DTF Gangsheet Builder, ensure designs are high-resolution and arranged properly. Conduct test prints to adjust settings like temperature and pressure for different fabrics, and work in a clean environment to avoid contamination. Regularly experiment and refine your technique based on the results.

| Step | Description |

|---|---|

| 1. Prepare Your Designs | Ensure high-resolution images, arrange designs on gangsheet, and set color mode to CMYK. |

| 2. Print the Designs | Load specialized PET film, select printer settings, and print designs on the film. |

| 3. Apply Adhesive Powder | Sprinkle adhesive powder on wet ink and cure in a heat oven or press. |

| 4. Transfer the Design | Set heat press, position film on garment, press, cool, and peel off film. Final cure may be needed. |

Summary

DTF Gangsheet Builder is an essential tool for anyone looking to create premium quality prints. This method allows users to efficiently print multiple designs together, resulting in cost savings and reduced waste. Following the clear steps laid out in this guide, including preparations, printing, applying adhesive, and transferring designs, can lead to vibrant and durable results that stand out. As you continue to master the DTF Gangsheet Builder, you will not only elevate your printing skills but also bring distinctiveness to your custom garment offerings. Embrace the endless creative possibilities and transform your designs into stunning realities.